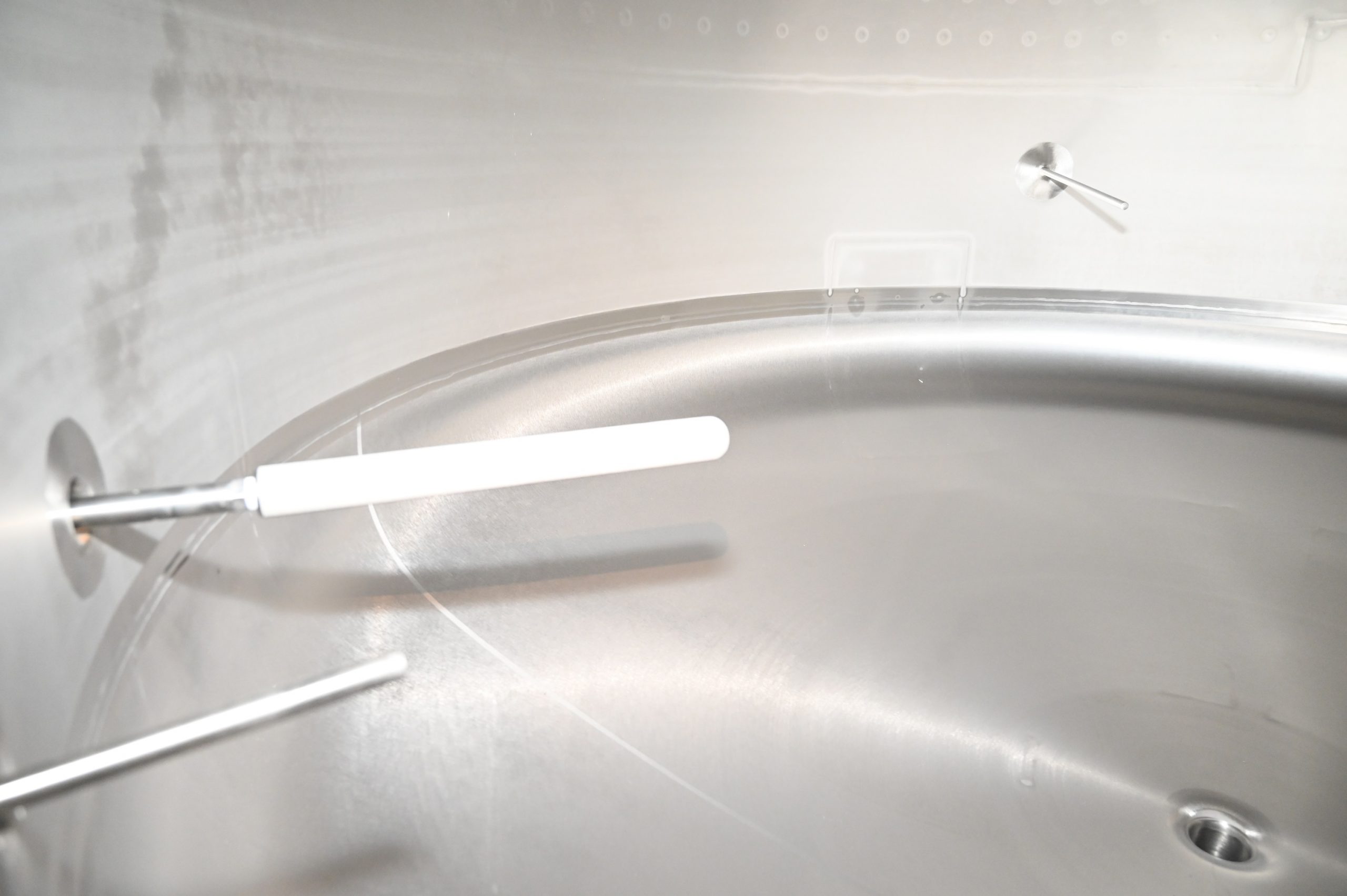

80BBL Stainless Steel Brite Beer Tanks With Painted Outer Surface

Stainless steel jacketed brite tanks are specialized vessels used in the brewing industry to hold and store beer prior to packaging. The tanks are typically made of high-quality stainless steel and are equipped with a double-wall jacket that allows for temperature control. The jacketed design of the tank allows for glycol or chilled water to be circulated through the space between the inner and outer walls, regulating the temperature of the beer inside. Because the 80bbl brite tanks will be placed outdoor, the local government require the outer surface of the tanks need to be painted.

Advantages

|

|

Key Considerations for Painted Stainless Steel Fermentation Tanks

-

Local Regulations and Standards:

- Understand and comply with local regulations regarding the painting of stainless steel fermentation tanks. These may include environmental regulations, safety standards, and industry-specific guidelines.

- Ensure that the paint and painting process meet any relevant food safety standards if the tanks will be used in the food or beverage industry.

-

Material and Paint Selection:

- Choose the appropriate type of stainless steel (e.g., 304 or 316L) based on the application and environmental conditions.

- Select a paint that is suitable for stainless steel surfaces, providing adequate adhesion, durability, and resistance to chemicals, heat, and moisture.

- Ensure the paint is non-toxic and safe for use in environments where the tank may come into contact with consumable products.

-

Surface Preparation:

- Properly prepare the stainless steel surface before painting to ensure good adhesion. This typically involves cleaning, degreasing, and possibly abrasive blasting or applying a suitable primer.

-

Painting Process:

- Apply the paint in a controlled environment to ensure consistent quality and adherence to safety regulations.

- Use the appropriate painting method (e.g., spray, brush, or dip coating) based on the tank’s design and the paint’s properties.

- Ensure that the paint is applied evenly and at the correct thickness to provide adequate protection and finish.

-

Quality Control:

- Implement strict quality control measures to check for defects in the paint application, such as bubbles, peeling, or uneven coating.

- Perform inspections and tests to ensure the painted surface meets the required standards and specifications.

Parameter

|

|

Standard product features:

Brite Beer Tank w/ 20% head space.

Design pressure 30-45psi or 2-3bar.

Interior shell: SUS304, thickness 3mm.

Exterior shell: SUS304, thickness 2mm.

Interior and exterior finish bright polish to 2B, hygienic surface.

Options of vertical or horizontal orientation.

Dual ports for racking and discharge/CIP with butterfly valve and fittings.

Side or Top man way door, shadowless.

Dimple glycol cooling jackets with glycol inlets and outlets.

Polyurethane foam insulation, thickness 80mm/>3” on side and bottom.

Fully welded exterior shell.

4 legs with levelling foot pads.

CIP arm and spray ball.

2” Vacuum relief at 2bar.

Pressure relief valve at 30-45psi as standard.

Sanitary pressure gauge.

1.5”sample valve.

Carbonation/sinter stone with one way check valve.

Quick connect gas valve.

Lifting Lugs.

Thermowell.

OPTIONS:

Additional blow off pipework.

Dry hopping port

Larger drain ports.

Upgrade drain port size

Racking arm

Contact

Contact

E-mail

E-mail

Message

Message