Blog

04-

15

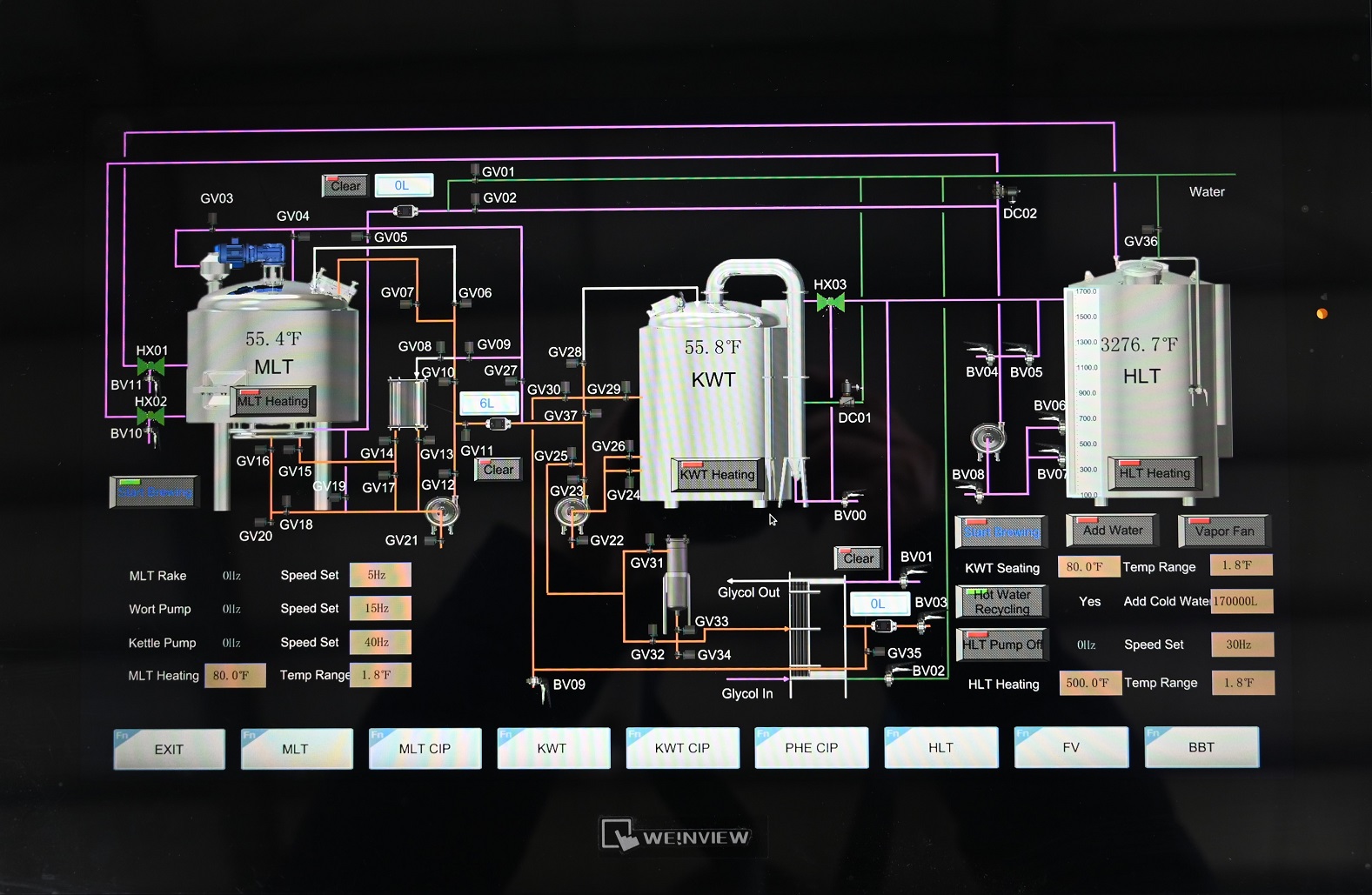

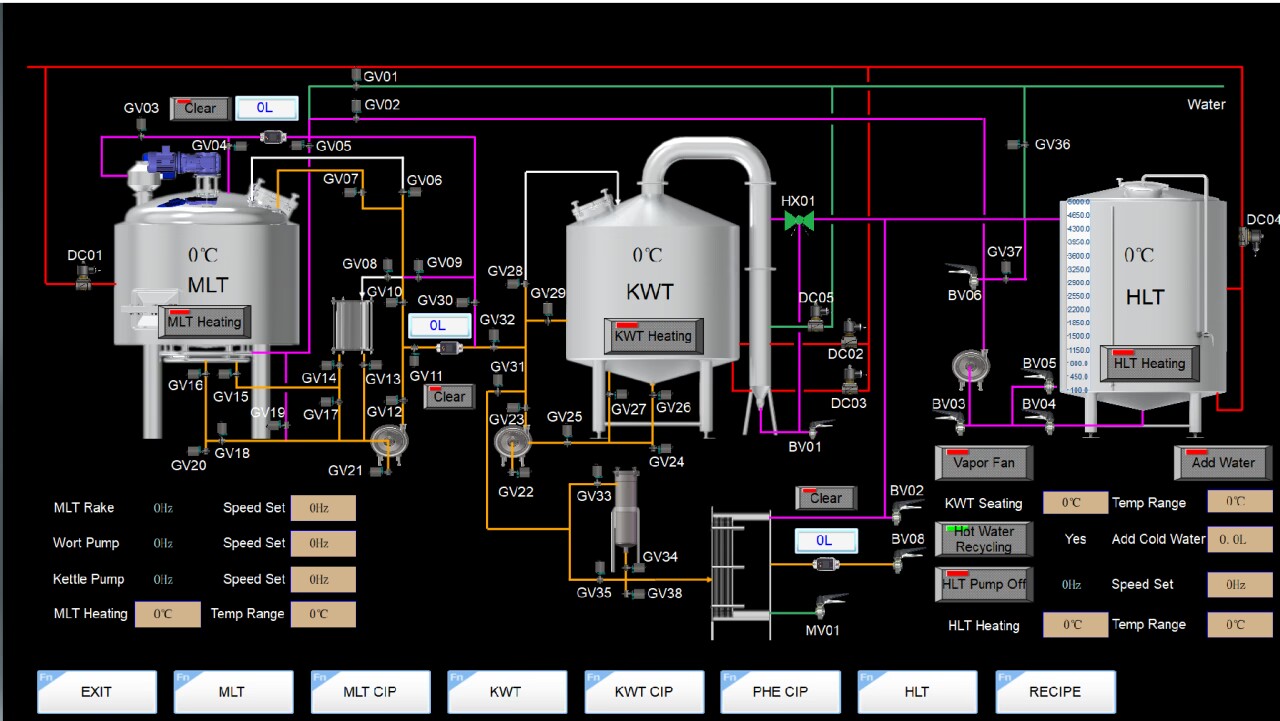

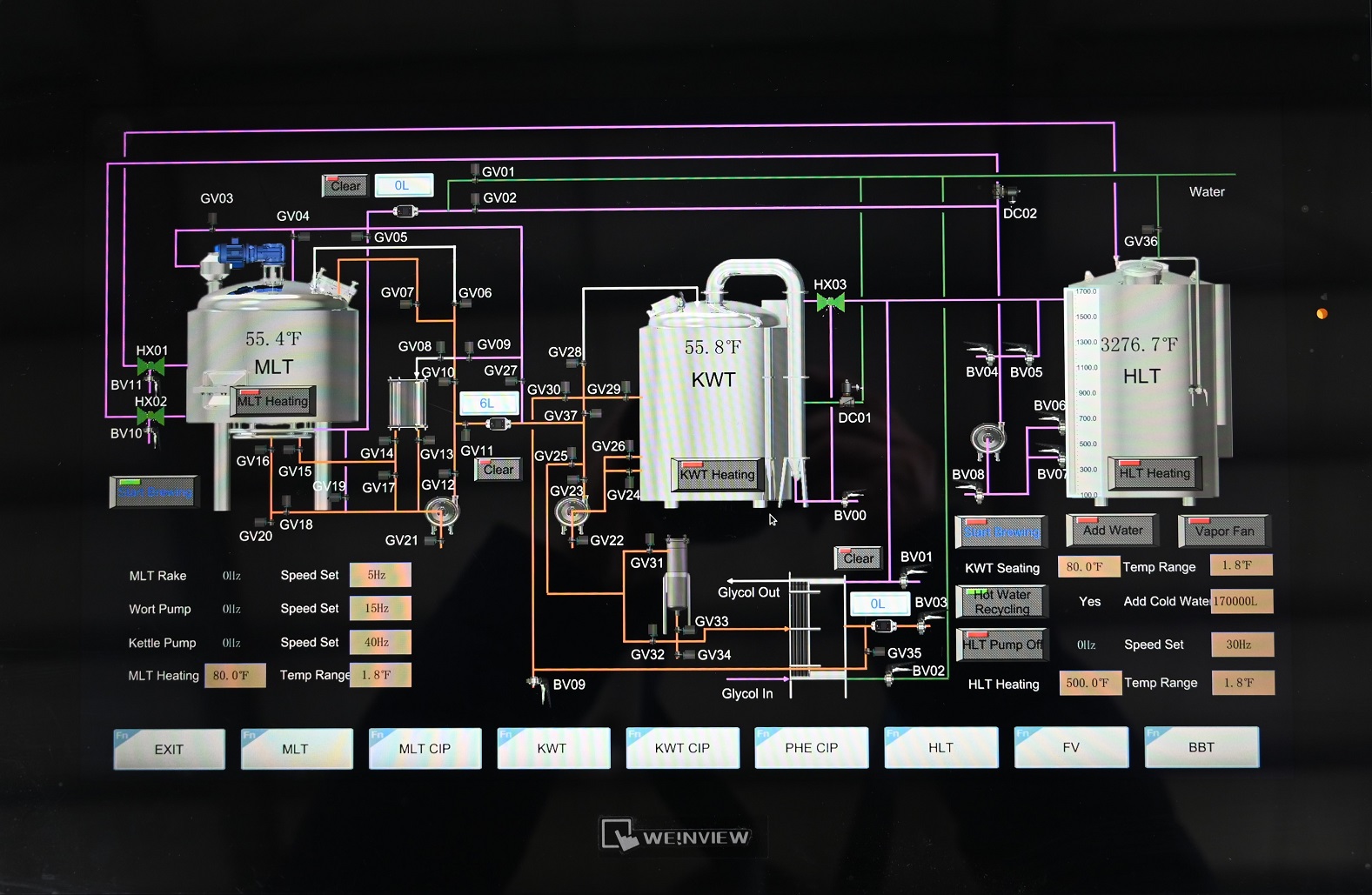

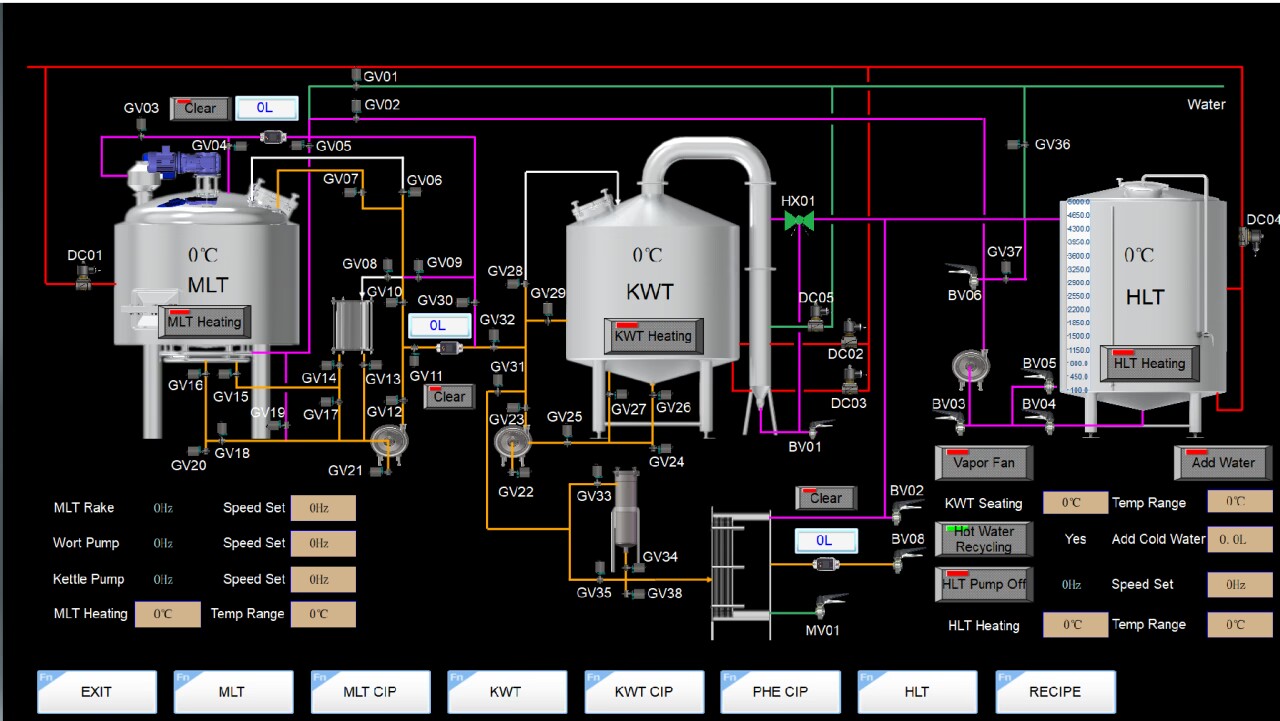

NFE 2000L Automated Brewing System Starts to Work in Belgium!

More

05-

27

NFE 2000L Automated Brewing System Starts to Work in Belgium!

More

05-

27

How to Choose the Right Beer Brewing Equipment, Automatic or Semi-automatic?

More

05-

22

How to Choose the Right Beer Brewing Equipment, Automatic or Semi-automatic?

More

05-

22

What is the essential equipment of a distillery?

More

04-

28

What is the essential equipment of a distillery?

More

04-

28

Welcome to our booth #824 at CBC2025 in Indianapolis!

More

03-

05

Welcome to our booth #824 at CBC2025 in Indianapolis!

More

03-

05

NFE engineer has installed a new 10bbl brewery for our clients in the USA!

More

02-

10

NFE engineer has installed a new 10bbl brewery for our clients in the USA!

More

02-

10

New 2000L Automatic Brewing System was Shipped to Belgium!

More

New 2000L Automatic Brewing System was Shipped to Belgium!

More

NFE 2000L Automated Brewing System Starts to Work in Belgium!

More

05-

27

NFE 2000L Automated Brewing System Starts to Work in Belgium!

More

05-

27

How to Choose the Right Beer Brewing Equipment, Automatic or Semi-automatic?

More

05-

22

How to Choose the Right Beer Brewing Equipment, Automatic or Semi-automatic?

More

05-

22

What is the essential equipment of a distillery?

More

04-

28

What is the essential equipment of a distillery?

More

04-

28

Welcome to our booth #824 at CBC2025 in Indianapolis!

More

03-

05

Welcome to our booth #824 at CBC2025 in Indianapolis!

More

03-

05

NFE engineer has installed a new 10bbl brewery for our clients in the USA!

More

02-

10

NFE engineer has installed a new 10bbl brewery for our clients in the USA!

More

02-

10

New 2000L Automatic Brewing System was Shipped to Belgium!

More

New 2000L Automatic Brewing System was Shipped to Belgium!

More