Semi-auto Bottle Filler&Capper

The equipment is a semi-automatic four-head bottle filling and capping machine, which is applicable to the glass

bottles and aluminum bottles with a volume of 330-1000ml. The beer filling is carried out according to the isobaric

principle, finally capping is finished easily. The advantages of the equipment are PLC program control filling

process automatically, simple structure, easy to operate, small area, which is suitable for small breweries and

bars with capacity of 300-360 bottles /hour(330ml bottle).

Advantages

1 Main structure::

The machine is consists of a filling unit, a canning unit and a CIP pipeline unit, wherein:

The filling unit includes:

Electrical control part, compressed air pipeline,CO2 pipeline, filling unit pipeline, cylinder unit, matching

positioning unit with bottle type, etc.

The capping unit includes: an electrical control part, a cylinder unit and a positioning unit matching the bottle type;

The CIP pipeline unit includes: CIP inlet, CIP outlet, and filling pipeline; When the customer successively

connects the CIP pipeline unit with the external CIP cleaning system, the purpose of cleaning and drying the filling

pipeline of the machine can be realized (note: the CIP cleaning unit can be customized according to customer’s

requirements, which is not a standard configuration of the machine).

2 The machine’s Function:

2.1 Through PLC’s instruction, each electrical components and valves are controlled in the sequential action to

realize the function of automatic filling and capping.

2.2 Working Process:

2.2.1 Filling Process:

Impact→Co2 purge*3→Isobaric→Fill→Pressure stabilization→ Pressure Release → Stop → Move to Capping

station

2.2.2 Capping Process: Pressing → Capping

2.2.3 CIP Process:

External CIP unit connect CIP portal →empty bottles in place → the beer source entrance is CIP recycling or

drain outlet (screen shot) → choose CIP in the control panel manually → press the start button once →enter the

“soaking & cleaning storage tank” program manually →Press the start button again after cleaning for a while →

the filling head is pressed down into the cleaning filling pipeline program → after cleaning for a while →Connect

the CIP inlet to the CO2 to empty the liquid in the storage tank and pipeline → press the stop button, the filling

head is lifted → press the stop button again →complete the CIP process

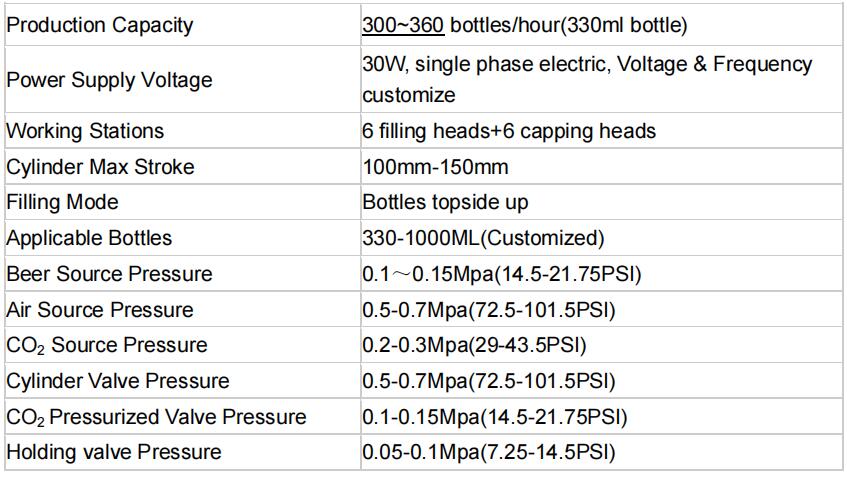

Parameter

Required utilities and main technical parameters:

1 Boundary Dimension: 2113mmx831mmx2209mm

Net weight:350Kg

2 Required Utilities:

The machine must be installed in the interior of clean workshop, with stable power supply, compressed air, CO2,

beer source supply.

①power ②CIP cleaning system ③Compressed air ④CO2 Source ⑤Open drainage ⑥Beer

3 Input conditions and parameters:

3.1 Power: 30W, single phase electric, Voltage & Frequency customize.

3.2 CIP cleaning system:

The customer needs to configure the CIP cleaning system by himself, which is used to clean the filling pipeline

before filling and after the filling work on the same day.

3.3 Requirement of Air Source: Oil-free Air Compressor, Air Compressor power needs to be 3-4KW, Discharge

rate>0.4M3 /Minute or >15CFM (Cubic feet per minute), Tank Volume > 100L, Air Pressure>0.5Mpa (72.5PSI).

3.4 Co2 Source: >0.3Mpa(43.5PSI).

3.5 Beer Source Requirement: Beer source pressure >0.12Mpa (17.4PSI).

4 Main Specification and Technical Parameters

Contact

Contact

E-mail

E-mail

Message

Message