1600 cans/hour Beer Canning Line

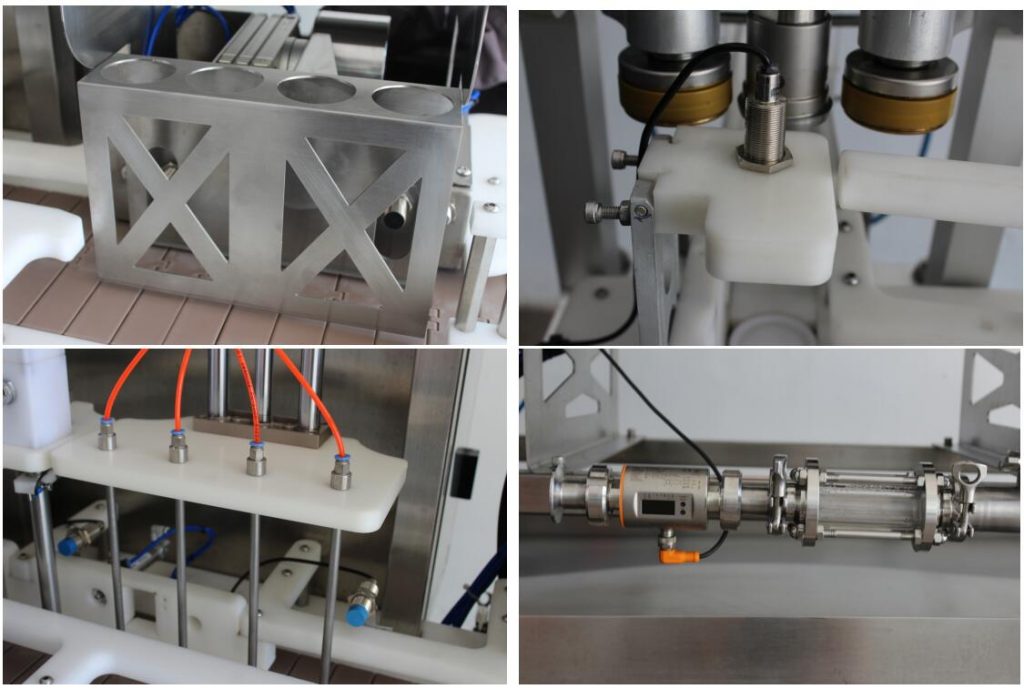

This NFE cans rinser/filler/seamer is specially designed for microbrewery to rinse can,fill beer into cans and seal cans automatically. Considering the limited area of most microbreweries, this machine is designed as a small size and fast filling speed, sanitary, movable, simple operation. The whole work is control by PLC programming. It can be used inline to be connected with other equipment, such as can depalletizer, labeler, date printer, etc. No Doubt that it is the ideal can filler for all the microbreweries.

Advantages

Specification and main technical parameters

|

Model |

BGF4/4/1 |

|

Machine type |

Linear |

|

Filling type |

Long tube isobaric filling for beer |

|

Quantity of rinsing position |

4 |

|

Quantity of filling valve |

4 |

|

Quantity of seaming head |

1 |

|

Height of operating platform(mm)(H) |

1040 |

|

Dimension of machine Figure(mm) |

2830*910*1850 |

|

Net weight(Kg) |

340KG |

|

Capacity |

800-1500cans/H(12OZ) |

|

Power |

3.5KW |

|

Demanded size of can |

12oz,16oz |

|

Main material of machine |

SUS304 |

Parameter

Technical requirements

|

Sealing pressure |

0.2-0.3Mpa(30-45PSI) |

|

Beer source pressure |

0.15-0.2Mpa(22-30PSI) |

|

Cylinder pressure |

0.5-0.7Mpa(73-102PSI) |

|

CO2 pressure |

0.15-0.20Mpa(23-30PSI) |

|

Rinsing water pressure in outlet |

0.15-0.2Mpa(22-30PSI) |

|

Time setting way |

Siemens PLC |

|

Filling control |

Precise flowmeter |

|

Movable or not |

Movable with wheels |

|

Voltage |

3 phase AC220V 60Hz |

A. Craft working process

Craft process: put can(on the sorting table)→press green button (AUTO mode)→Enter the rinsing staion→Enter the CO2 pre-purging station(CO2 in, and air out)→Enter the filling station (the number of cans is a multiple of 4)→ filling cylinder down (beer valve is opened and filling begins, isobaric filling)→ filling is completed (the electrode detection of the four stations should be connected, and the position of the electrode can be adjusted according to different can types)→can enters the falling lid station→fall lid is completed to enter the seaming station→seaming is completed to enter the spray station→completed

B.Filling process: First step is low flow filling,Second step is High flow filling,Third step is add beer and forming filling and this step with 1 times add beer ( Each station could add 1 times setting)

C.After seaming, there is water rinse function which could adjust manually to control flow state and washing cans.

Contact

Contact

E-mail

E-mail

Message

Message