Keg Washer

The keg washer has been designed as a self-contained and reliable automatic keg processing machine. Although kegs are loaded and unloaded manually, all washing operations are fully automatic for consistent high quality results.

The information, instructions, and warnings contained in this document have been prepared to clarify operational and maintenance procedures. If followed carefully, they should provide safe, long, and reliable service from the machine.

Proper maintenance and the use of approved spare parts will extend the life of the system and its reliability, while the use of any non-approved spare parts may void any warranties or guarantees; actual or implied.

Advantages

- This beer keg washer uses the Siemens S7-200 controller and Smart touch screen, Schneider parts, AirTAC solenoid valve.

- Washing part includes washing washing, caustic washing, acid washing, steam sterilize.

- The beer kegging machine needs connect with hot water, steam, CO2 and compressed air.

- The beer kegging machine has the detection function, can detect if the pipes with the liquid.

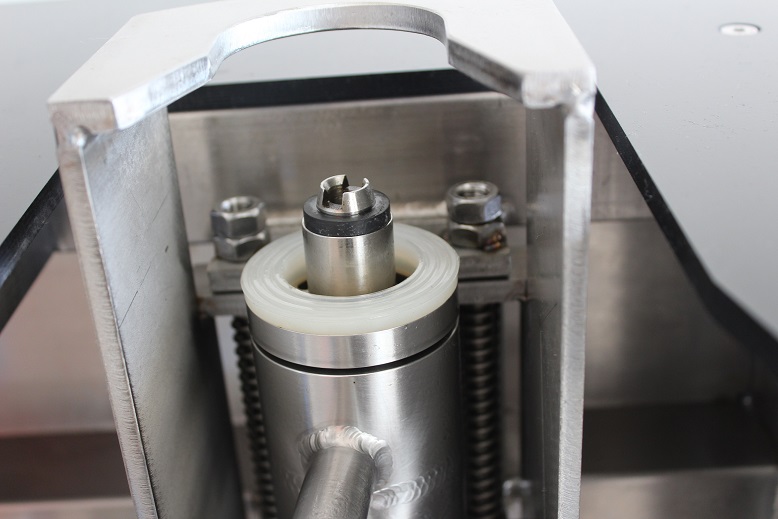

- The whole keg washer machine use the stainless steel AISI304. All pipe weldings use orbital welding system. The inside and outside of pipes are clean and sanitation.

Parameter

Keg washing working procedure: Lock →air blowing/drain off→ hot water 1 washing→air blowing/drain off→ hot caustic washing→air blowing/to caustic box→hot water 2 washing→air blowing/drain off→ acid washing→air blowing/drain off→brew water rinse cooling keg →co2 blowing/drain off→co2 pressure preparing→cylinder return

Contact

Contact

E-mail

E-mail

Message

Message