100L Homebrew Brewhouse

Our 100L brewing systems are ideal for homebrew. These nano systems are available in electric and direct fire and can also be used as a pilot brewing system in your brewery.

1) All the tanks insulation use argon arc welding and inner tank will do pickling and passivation or mirror polishing;

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts;

3) All the steam heating beer brewery tank will do water and pressure test when finishing. Pressure test is 2-4bar;

4) Closed grant system improves runoff performance;

5) Variable speed drives on pumps, motors and agitators;

6) Stainless steel work platform for integrity, no rusting and long life;

Advantages

1. Complete, new, and high quality configuration.

2. Auxiliary systems selection of leading and imported brand.

3. The auxiliary systems are long life, high-performance, high-quality, low-loss.

4. Certified stainless steel(304,316) material for all tanks.

5. Electrical accessories reach UL, cUL, CE, PED, export standards.

6. Supporting auxiliary system voltage and frequency match your standard exactly.

7. New production technics.

8. Stable quality, high performance, strict quality control.

9. All the equipment are adopted 100%TIG welded joints, mirror Polishing.

10. CAD layouts, installation assistance, assembly, training.

Parameter

|

No. |

Name |

Specification |

Quantity |

Remarks |

||

|

|

||||||

|

01 |

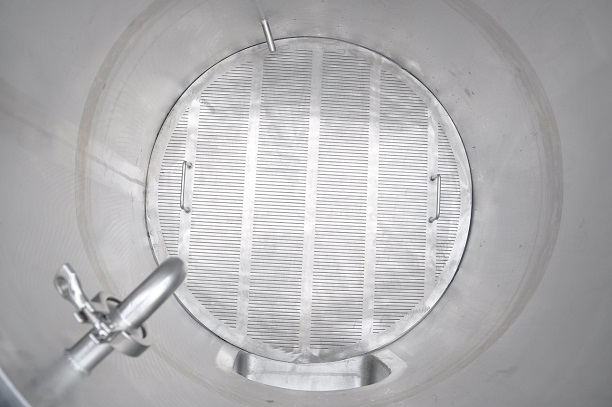

Mash Lauter tun |

1BBL |

1 |

Stainless steel 304 Effective volume: 1BBL Total capacity:160L, Rock wool insulation, The thickness of insulation:40mm, The thickness of inner body:2mm, Open top, with cover, Milled false bottom, Side spent grain door, with removable chute PT100 thermo sensor Valves assembly |

||

|

02 |

Boiling kettle/Whirlpool tank |

1BBL |

1 |

Stainless steel 304, Electric heating Effective volume: 1BBL Total volume: 260L, Rock wool insulation, The insulation thickness: 40mm, The inner body thickness 2mm, The cladding thickness: 2mm, With open top cover PT100 thermo sensor Slopping bottom with two outlet Valves assembly |

||

|

03 |

HLT |

1BBL |

|

Stainless steel 304, Electric heating With HERMS coil (for heating wort of mash tun) Electric heating power:4KW Effective volume: 1BBL Total volume: 160L, Rock wool insulation, The insulation thickness: 40mm The inner body thickness 2mm The cladding thickness: 2mm With Coil pipe for wort With open top cover PT100 thermo sensor Valves assembly |

||

|

04 |

Wort Pump |

Flow Rate: 46L/M Pump Lift: 1.8m |

2 |

Power: 15W |

||

|

05 |

Hops Filter before heat exchanger |

|

1 |

|

||

|

06 |

Heat Exchanger |

0.7m2 |

1 |

Stainless steel, single stages with Oxygenating device |

||

|

07 |

Piping and valves |

ISO: Φ25 |

1 |

Stainless steel304, sanitary grade |

||

|

08 |

Movable cart |

|

1 |

Stainless steel 304 |

||

|

09 |

Small rake |

|

1 |

|

||

|

10 |

Control Panel |

Stainless steel 304 |

1 |

Push buttons control panel Control temperature of boiling kettle and HLT Display temperature of mash/lauter tun Control pump CE rated |

||

Contact

Contact

E-mail

E-mail

Message

Message