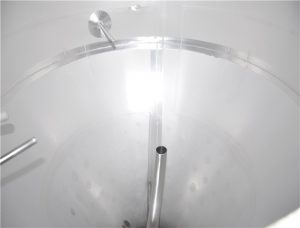

40BBL Beer Fermentation Equipment

NFE Professional stainless steel fermentation and maturation tank with cone for under pressure fermentation and maturation. The double jacket allows to connect a cold water source for a controlled fermentation process. The yeast concentrates at the bottom of the cone. Drained before the maturation process, it can be reused for future brews. Fermentation and maturation can thus take place in one tank.

Made from 304 or 316L stainless steel coming with either dual or multi-zoned glycol jackets, NFE stainless steel conical fermentation tanks are the ultimate choice in fermenting wort into beer.

Advantages

1) All the tanks insulation use argon arc welding and inner tank will do pickling and passivation or mirror polishing;

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) All the steam heating beer brewery tank will do water and pressure test when finishing. Pressure test is 2-4bar;

4) Dimple jackets are standard on insulated vessels, providing greater cooling efficiency and added vessel integrity.

5)All fermentation vessels feature jackets on the cone for greater cooling efficiency.

6) Fermentation vessels have half batch capabilities.

1. Complete, new, and high quality configuration.

2. Auxiliary systems selection of leading and imported brand.

3. The auxiliary systems are long life, high-performance, high-quality, low-loss.

4. Certified stainless steel(304,316) material for all tanks.

5. Electrical accessories reach UL, cUL, CE, PED, export standards.

6. Supporting auxiliary system voltage and frequency match your standard exactly.

7. New production technics.

8. Stable quality, high performance, strict quality control.

9. All the equipment are adopted 100%TIG welded joints, mirror Polishing.

10. CAD layouts, installation assistance, assembly, training.

Parameter

|

SPECIFICATIONS FOR COMPLETE SET BEER BREWING EQUIPMENT |

||

|

No. |

Name |

Specification |

|

1 |

Fermentation tanks |

Interior and exterior finish polished to a sanitary finish Interior finish pickled and passivated Exterior brushed, #4 finish Fully welded exterior shell 60 degree cone bottom, with an average of 25% head space Rotating racking port Glycol cooling jacket on cone and bottom Inoxpa butterfly valves, sample valve, 2” pressure vacuum relief valve RTD Probe Tension braces on legs Sanitary tri-clamp connections |

Contact

Contact

E-mail

E-mail

Message

Message