7BBL Automatic Controlled Direct-fired Brewing System

At NFE, we understand that every brewery is unique, with specific production goals, space requirements, and creative ambitions. That’s why our brewhouses come in a variety of configurations, each customized to meet our clients’ individual needs. From port locations and sizes to vessel dimensions, each system is adapted based on our customers’ preferences, resulting in brewhouses that are rarely identical.

Our most popular setup is the 2-vessel brewhouse, which combines a mash and lauter tun with a kettle and whirlpool vessel, providing an efficient and streamlined option for many brewers. For those looking to expand brewing capabilities, we also offer a 3-vessel configuration, allowing brewers to separate either the mash and lauter or the kettle and whirlpool into dedicated vessels. This flexibility enables brewers to enhance control over each stage of the brewing process.

For those looking to scale up production even further, our brewhouses can be designed to accommodate a 4-vessel configuration where each step in the brewing process is assigned to its own dedicated vessel. This setup allows for greater volume and efficiency, making it an ideal choice for brewers focused on boosting output.

We believe in empowering brewers to work with equipment that reflects their preferences and production goals. Whether you’re starting with a 2-vessel brewhouse or expanding to a more complex setup, NFE is committed to providing high-quality, customizable brewing solutions that respect your creativity and expertise.

Advantages

|

|

|

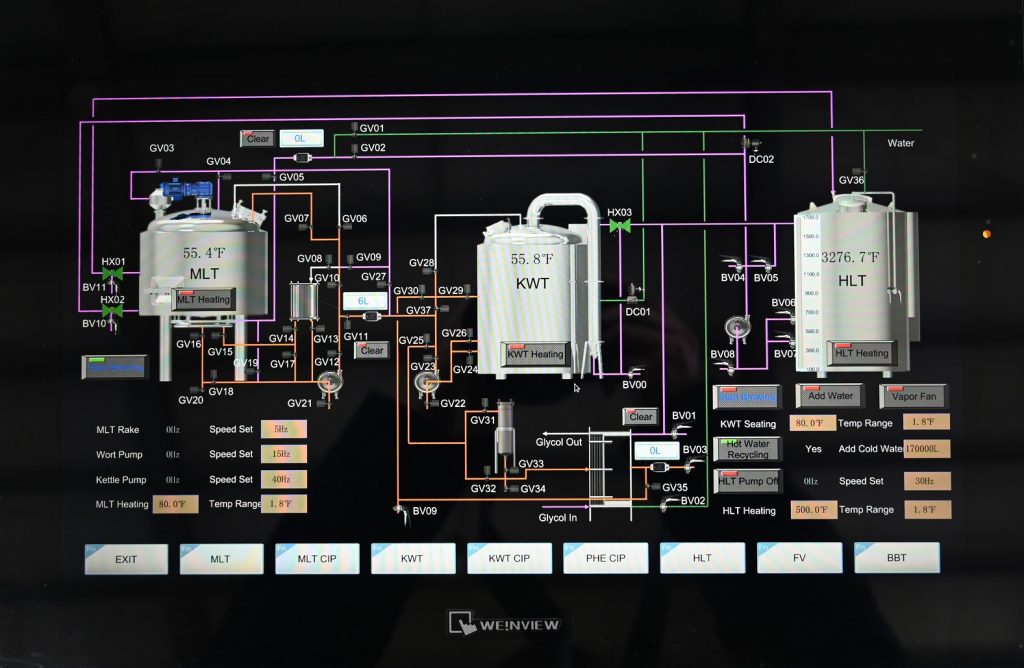

NFE’s fully automated mashing system offers a streamlined, high-precision brewing experience, making it an ideal choice for small and medium-sized breweries and craft beer brands with high standards for quality. By combining advanced automation with intelligent operation, this system brings significant advantages to craft brewing:

1. Precise Control for Consistent Brewing Quality

Equipped with precise controls for temperature, timing, and agitation, NFE’s automated mashing system maintains optimal conditions throughout the mashing process. This ensures batch-to-batch consistency, helping brewers deliver a high-quality product every time.

2. Intelligent Operation for Simplified Brewing

The system’s automation simplifies the brewing process, allowing brewers to set key parameters effortlessly through an intuitive control panel. This reduces manual labor, making the system highly user-friendly and boosting management efficiency.

3. Labor Savings and Increased Efficiency

Once parameters are set, the fully automated system completes each stage of the mashing process autonomously—from heating and agitation to cleaning—minimizing the need for manual intervention. This not only reduces labor costs but also shortens production times, significantly increasing brewing efficiency.

4. Energy-Efficient Design for Reduced Operating Costs

Designed with energy efficiency in mind, the system precisely controls heating duration and intensity to reduce unnecessary energy consumption. Scientific design of the heating and cooling systems allows for rapid temperature changes while keeping energy use low, helping brewers lower their operating costs.

5. Easy Cleaning and Maintenance

With an integrated CIP (clean-in-place) system, the system automatically executes cleaning procedures after each mashing cycle, ensuring hygiene standards and reducing cleaning time. Built for durability and easy maintenance, the system minimizes downtime and long-term maintenance costs.

NFE’s fully automated mashing system not only improves production efficiency but also delivers consistent quality and flavor for every batch. With its high efficiency, energy savings, and intelligent design, it stands out as the ideal choice for breweries seeking an advanced, reliable brewing solution.

Parameter

|

|

|

|

|

|

|

1. Brewhouse |

|||||

|

01 |

Mash/lauter tun |

7 bbl |

1 |

1. Stainless steel304, 2. Effective volume: 7 bbl; total volume: 1150L 3. With rake, motor with reduer, variable frequency, with chain to lift the scraper up and down 4. Side spent grain door, with guide plate 5. Rockwool insulation, thickness: 80mm; 6. The inner tank thickness is 3mm; cladding thickness: 2mm 7. Milled false bottom 8. At the bottom of false bottom with back flashing water valve 9. Liquid level sight tube; 10. Top full glass manway 11. With grist hydrator 12. sparging coil pipes; CIP spray ball 13. With sight light. 14. 4 stainless steel legs |

|

|

02 |

Boiling Kettle/whirlpool Tun |

7 bbl |

1 |

1. Sanitary Stainless steel 304 2. Effective volume: 7 bbl; total volume: 1420L 3. Direct fired, with fireproof material insulated fire chamber and a section of fire-resistant material insulated smoke stack; with port to connect with customer’s gas burner; 4. Rockwool insulation, thickness: 80mm; 5. Inner body thickness 3mm, cladding thickness 2mm; 6. Rotary CIP spray balls; 7. Tangential whirlpool entry 8. liquid level sight tube; 9. PT100 temperature probe 10. Top glass manway door, 11. with sight light; 12. 4 stainless steel legs |

|

|

03 |

Wort Pump |

5,000L/h |

2 |

Sanitary stainless steel 304 food grade pump, variable frequency control, Flow Rate: 5,000L/h, Pump Lift: 24m |

|

|

04 |

Steam indoor condensate device |

|

1 |

Condensate the steam that generated in the brewkettle, and drain condensate water directly to the sewer. With a 0.37KW air blower to draw the steam generated in the brewkettle to the stack, a tube type cooler to condensate the steam, and city water inlet and outlet. |

|

|

05 |

Hot water tank |

15 BBL |

1 |

Stainless steel 304, Effective capacity:15bbl, Direct fired, with fireproof material insulated fire room and smoke stack; with port to connect with customer’s gas burner; Man hole inspection and entry point, PT100 temperature probe Sight gauge for water level, with scale plate with rotating spray ball With overflow pipe |

|

|

06 |

Hot water pump |

5,000L/h |

1 |

Sanitary stainless steel 304 food grade pump, variable frequency control, Flow Rate: 5,000L/h, Pump Lift: 24m |

|

|

07 |

Wort grant |

20L |

1 |

Stainless steel 304 and glass |

|

|

08 |

Hops back |

30L |

1 |

Assorted, install on pipeline between whirlpool tank and heater exchanger |

|

|

09 |

Flow meter |

|

assorted |

IFM brand. Monitor flow of the strike water after cold and hot water mixed. |

|

|

10 |

Pressure sensor |

|

1 set |

IFM brand pressure sensors, PM1608/E33601/E11252 |

|

|

11 |

Liquid level switches |

|

Assorted |

|

|

|

12 |

Heat Exchanger |

8m2 |

1 |

Stainless steel 304, two stages, six flows |

|

|

13 |

Work Platform with bottom skid |

|

1 |

Stainless steel 304, with stairs, handrails For 3 vessels: mash/lauter tun, kettle/whirlpool tun and HLT |

|

|

14 |

Brewhouse Pipeline and valves |

|

1 set |

Stainless steel 304, sanitary grade pipes All the butterfly valves are pneumatic valves Pipes and valves for brewhouse vessels and PHE |

|

|

15 |

Wort Oxygenate device |

|

1 |

Stainless steel 304 pipe, used in wort outlet of heat exchanger, with titanium stick, sight glass, oxygenating port, temperature gauge |

|

|

16 |

Spent grain tool |

|

1 |

Stainless steel 304 |

|

|

2. Control System |

|||||

|

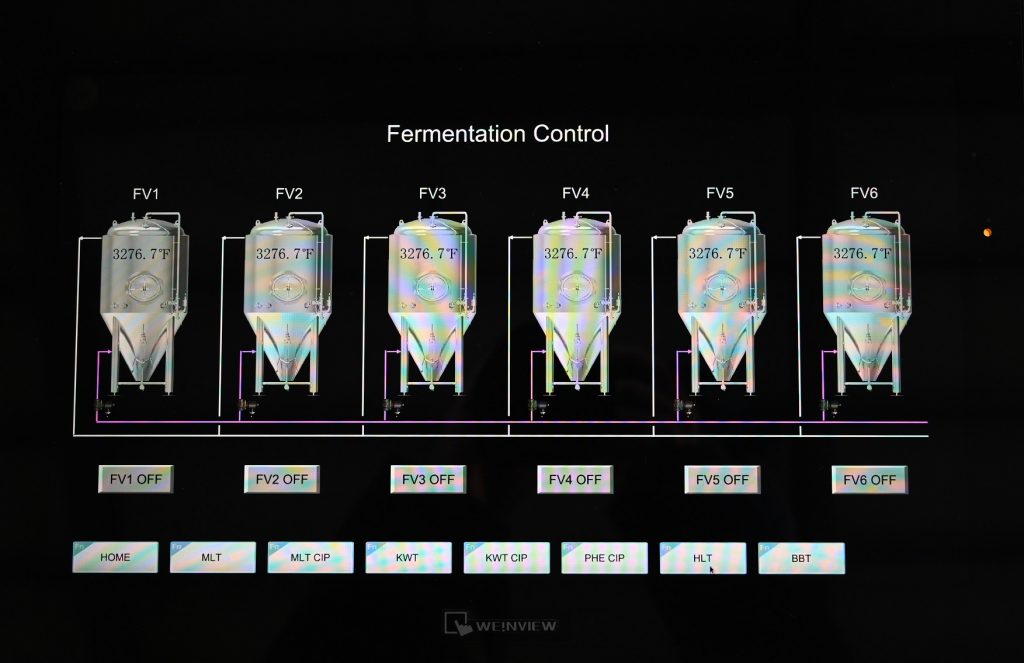

01 |

Control box |

Stainless steel 304 |

1 set |

1. Stainless steel 304 control box 2. Siemens PLC system and colorful touch screen 3. Mash/lauter tun rake and motor control 4. Kettle/whirlpool tun temperature control 5. Hot water tun temperature control 6. Pneumatic butterfly valves control 7. Pumps, motors and frequency converters control 8. Fermenters and bright beer tanks temperature control 9. Pressure sensor and liquid level swtich control 10. Danfoss frequency converter/VFD, Schneider breakers/relays 11. Can realize automatic control for each step. 12. UL rated control elements |

|

Contact

Contact

E-mail

E-mail

Message

Message