7BBL Automatic Direct Fired Brewhouse with DF HLT

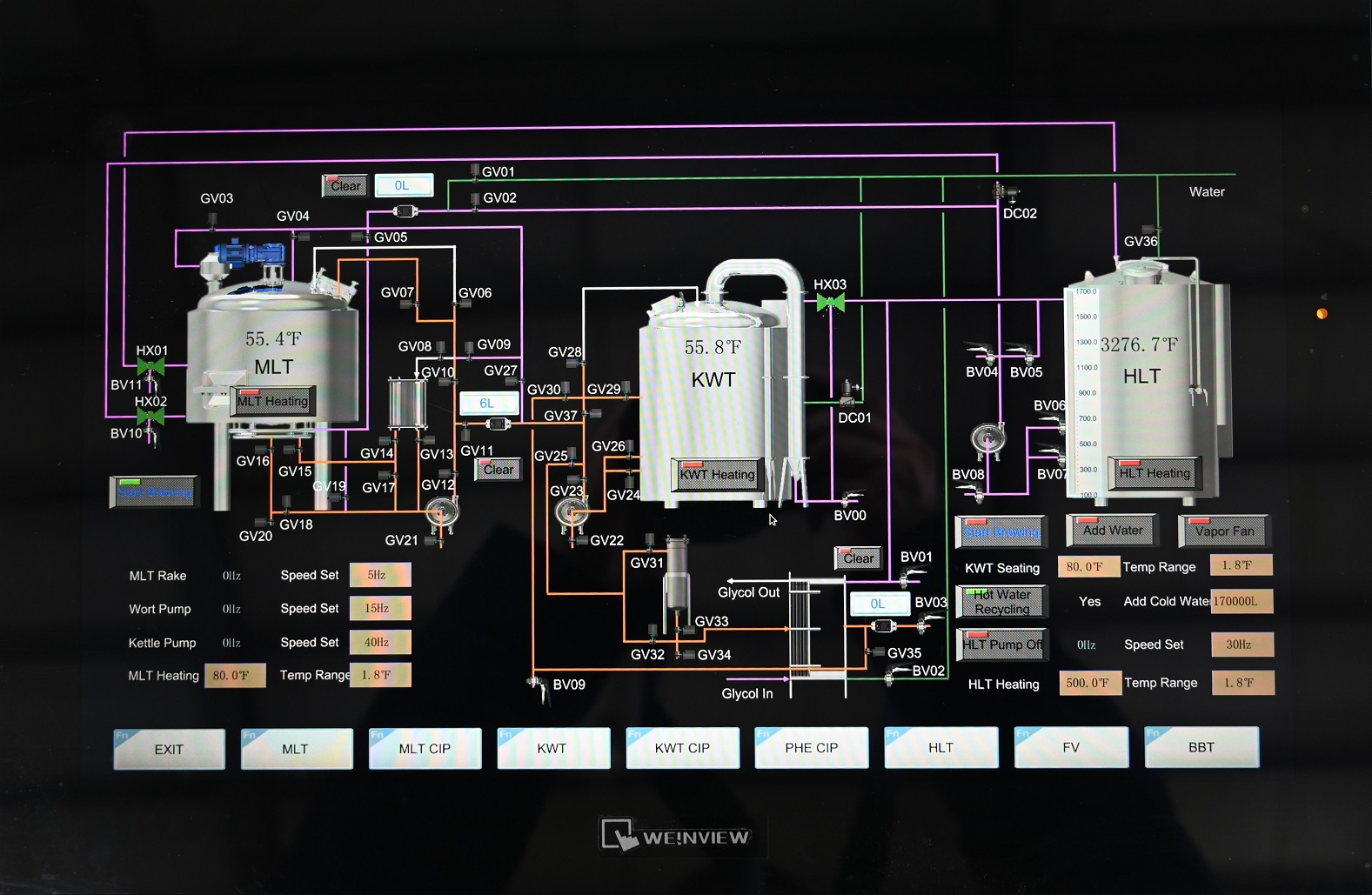

This set of 7bbl direct fired brewhouse is automatic with pneumatic valves and auto control.

The configuration of 7bbl brewhouse is as follows:

1. With 7bbl mash lauter tun,7bbl kettle whirlpool tun, 15bbl HLT

2. Kettle and HLT are gas direct fired.

3. Pneumatic butterfly valves+Siemens HMI+PLC with programming.

4. With IFM flowmeters,liquid level switches, pressure sensors,temperature sensors,etc.

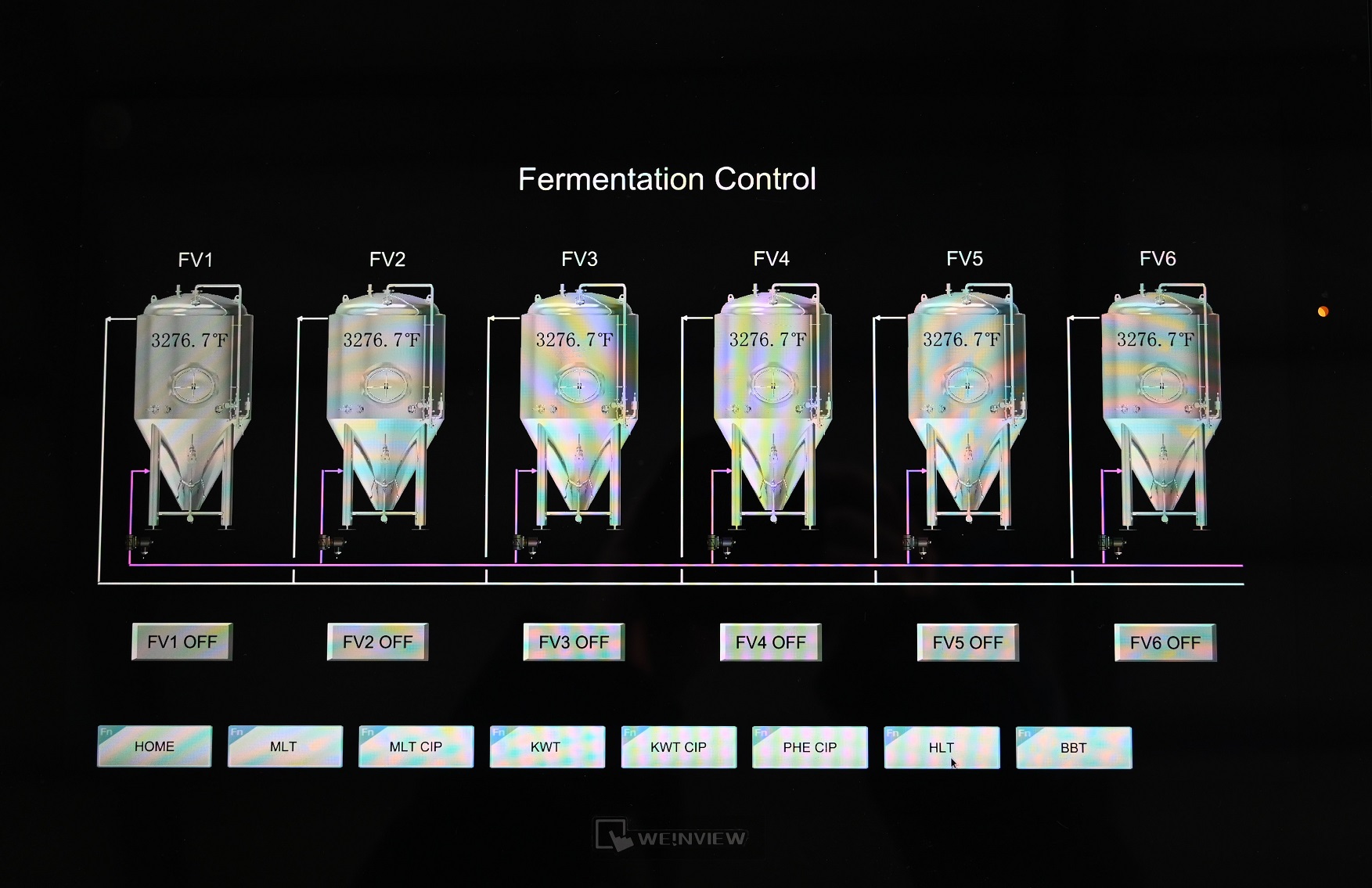

5. Control system includes the control points for 6 fermenters and 2 brite tanks.

6. Brewhouse is skid mounted.

Advantages

|

|

1) All the tanks insulation use argon arc welding and inner tank will do pickling and passivation or mirror polishing;

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts;

3) All the steam heating beer brewery tank will do water and pressure test when finishing. Pressure test is 2-4bar;

4) Closed grant system improves runoff performance;

5) Variable speed drives on pumps, motors and agitators;

6) Stainless steel work platform for integrity, no rusting and long life;

7)Automatic control, with pneumatic valves, pressure sensors, liquid level swithces, flow meters, etc.

Parameter

|

|

|

|

Standard product features:

Mash/Lauter tun:

- Mash lauter tun w/ 30% head space.

- Top glass manway with logo options.

- Hot/cold liquor blending pre grist hydrator.

- Motorized VFD reversible rakes & grain plow to aid with grain out.

- Internal LED lighting.

- Sparge ring and vorlauf assembly.

- Vorlauf sight glass.

- False bottom – wedge wire. (3mm)

- Multiple wort drain ports.

- Thermo-well and PT100 Thermocouple.

- Multiple CIP under flush ports.

- 20L SUS304 closed wort grant option.

- CIP spray balls – 360⁰ coverage.

- SUS304 Lifting Lugs.

- 4 SUS304 legs with levelling foot pads

Kettle/whirpool tun:

- Kettle/whirlpool combined vessel w/ 40% head space.

- Top glass manway with logo options.

- Internal LED lighting.

- Tangential wort inlet.

- 1.5″ side wort drain, behind trub baffle.

- 2″ drain outlet.

- CIP spray balls – 360⁰ coverage.

- SUS304 Lifting Lugs.

- 4 SUS304 legs with levelling foot pads.

Pump:

- VFD sanitary centrifugal pump.

- Made of 100% non-reactive, sanitary-finished, food-grade SUS304.

- Specific sanitary centrifugal pump designs for brewhouses, HLT, CLT, keg washers, hop cannons and lenticular filtration units.

- Standard flow rate of 10hL p/hr – 200hL p/hr.

- Standard lift of 18M – 24M.

Brewhouse Components:

Platform

- SUS304 working platform, with stairs and safety railing.

2-Stage Heat Exchanger

- Cold water and glycol stages for expedited knock out.

- High efficiency knock down.

- Easy cleaning and disassembly.

- Back flush capabilities.

- Set of spare plate gaskets included.

0² Oxygenation Assembly

- Sanitary sinter stone.

- SUS304 Ball valve & Gas quick connect.

- Allows to connect to 0² for wort oxygenation.

Valves and Piping

- SUS304 Sanitary fittings/valves/piping.

Brewhouse Electrical Control System

- Brewhouse, HLT, CLT & GT central control system.

- Controls for all VDF pumps.

- Temp gauges and switches to monitor steam heating.

Option:

HEATING METHOD

We offer all of the main heating methods which are:

- Electrical

We recommend electrical heating for brewhouses up to 840L/7BBL as above this size you start drawing serious power. It would be better to consider other options, but we will happily scale to larger brewhouses and HLTs depending on your needs. - Direct-Fire

We recommend direct-fire heating for brewhouses from 600L/5BBL as this gives enough area for the firebox under the vessels to work efficiently - Steam

We recommend this option for all size breweries if you are able to fit the costs in your budget and the equipment in your space. You get the best heating efficiencies and are able to utilize the steam in other areas of the brewery.

Contact

Contact

E-mail

E-mail

Message

Message