Blog

07-

13

Can You Start a Brewery In Your Garage?

More

05-

15

Can You Start a Brewery In Your Garage?

More

05-

15

Crafting Perfection: Introducing the 5BBL Brewing System

More

07-

07

Crafting Perfection: Introducing the 5BBL Brewing System

More

07-

07

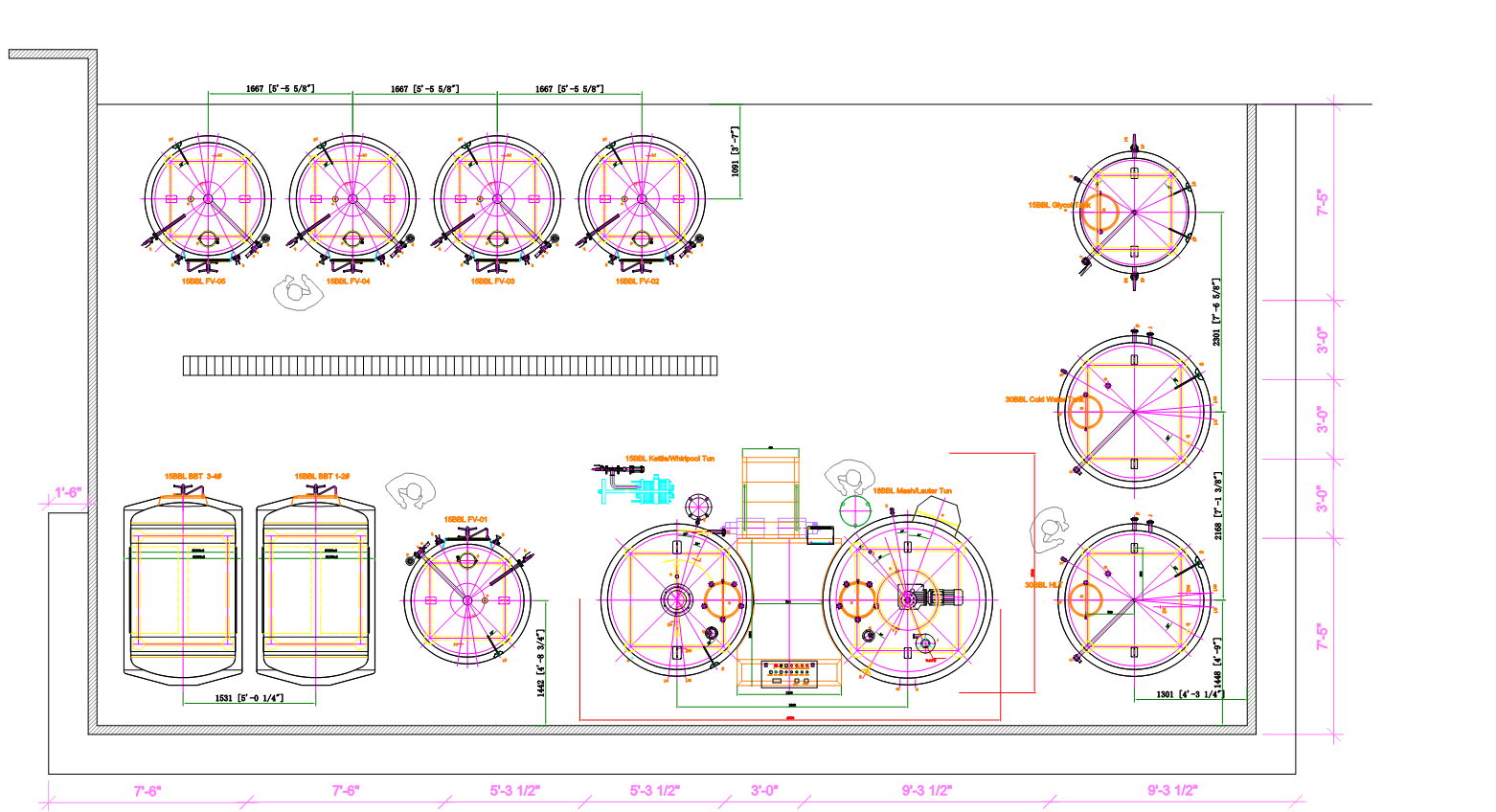

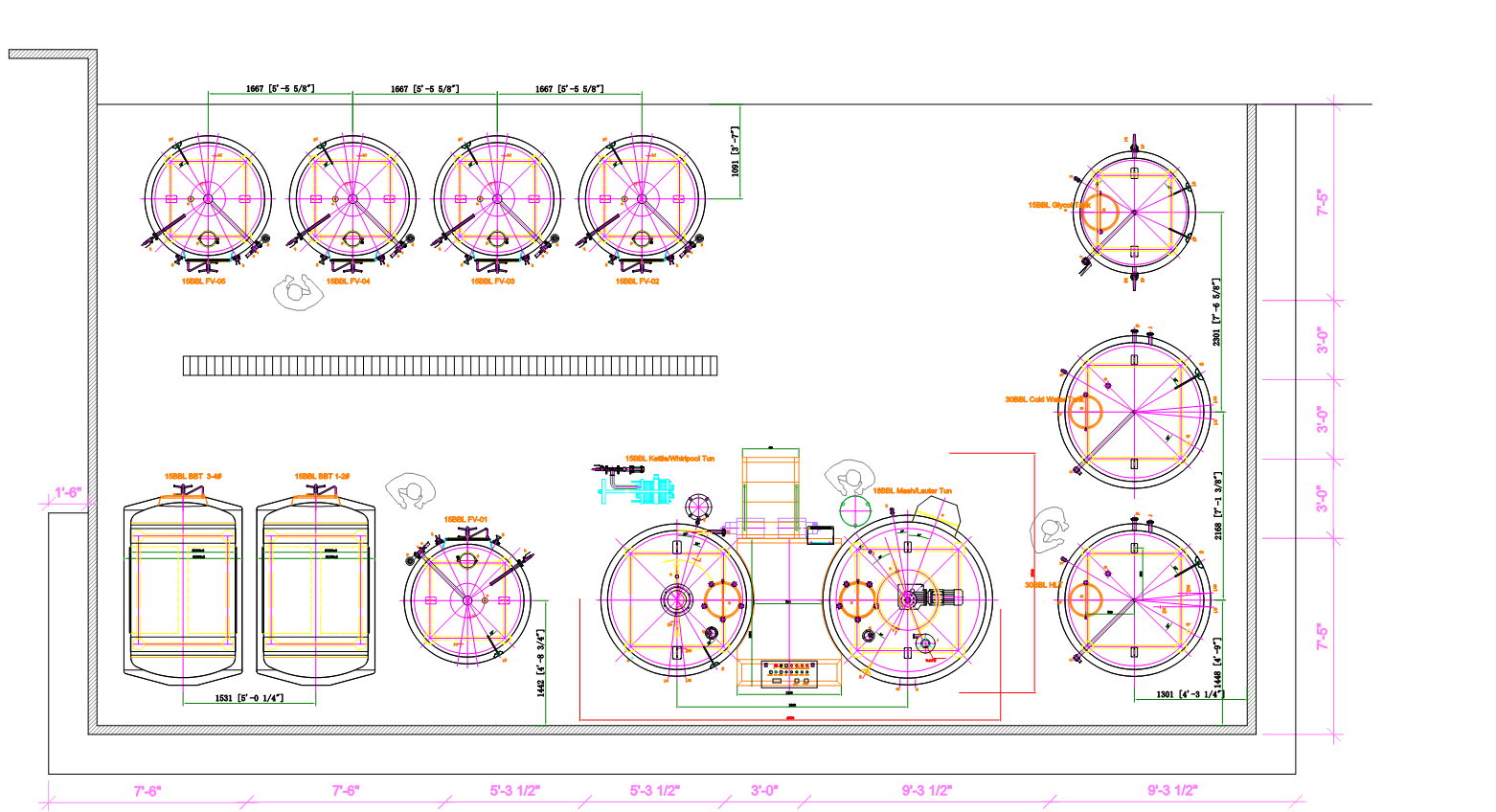

Brewery Layouts &Designs Consideration

More

10-

24

Brewery Layouts &Designs Consideration

More

10-

24

60BBL Beer Fermenters and 60BBL Brite Beer Tanks are finished and arranged for shipment!

More

09-

08

60BBL Beer Fermenters and 60BBL Brite Beer Tanks are finished and arranged for shipment!

More

09-

08

The Reasons And Solutions Of The Freezing For Beer Fermentation Tanks

More

06-

30

The Reasons And Solutions Of The Freezing For Beer Fermentation Tanks

More

06-

30

How To Install Draft Beer System

More

How To Install Draft Beer System

More

Can You Start a Brewery In Your Garage?

More

05-

15

Can You Start a Brewery In Your Garage?

More

05-

15

Crafting Perfection: Introducing the 5BBL Brewing System

More

07-

07

Crafting Perfection: Introducing the 5BBL Brewing System

More

07-

07

Brewery Layouts &Designs Consideration

More

10-

24

Brewery Layouts &Designs Consideration

More

10-

24

60BBL Beer Fermenters and 60BBL Brite Beer Tanks are finished and arranged for shipment!

More

09-

08

60BBL Beer Fermenters and 60BBL Brite Beer Tanks are finished and arranged for shipment!

More

09-

08

The Reasons And Solutions Of The Freezing For Beer Fermentation Tanks

More

06-

30

The Reasons And Solutions Of The Freezing For Beer Fermentation Tanks

More

06-

30

How To Install Draft Beer System

More

How To Install Draft Beer System

More