Brewery Layouts &Designs Consideration

When designing a brewery layout, there are several important considerations to keep in mind. Here are some key factors to consider:

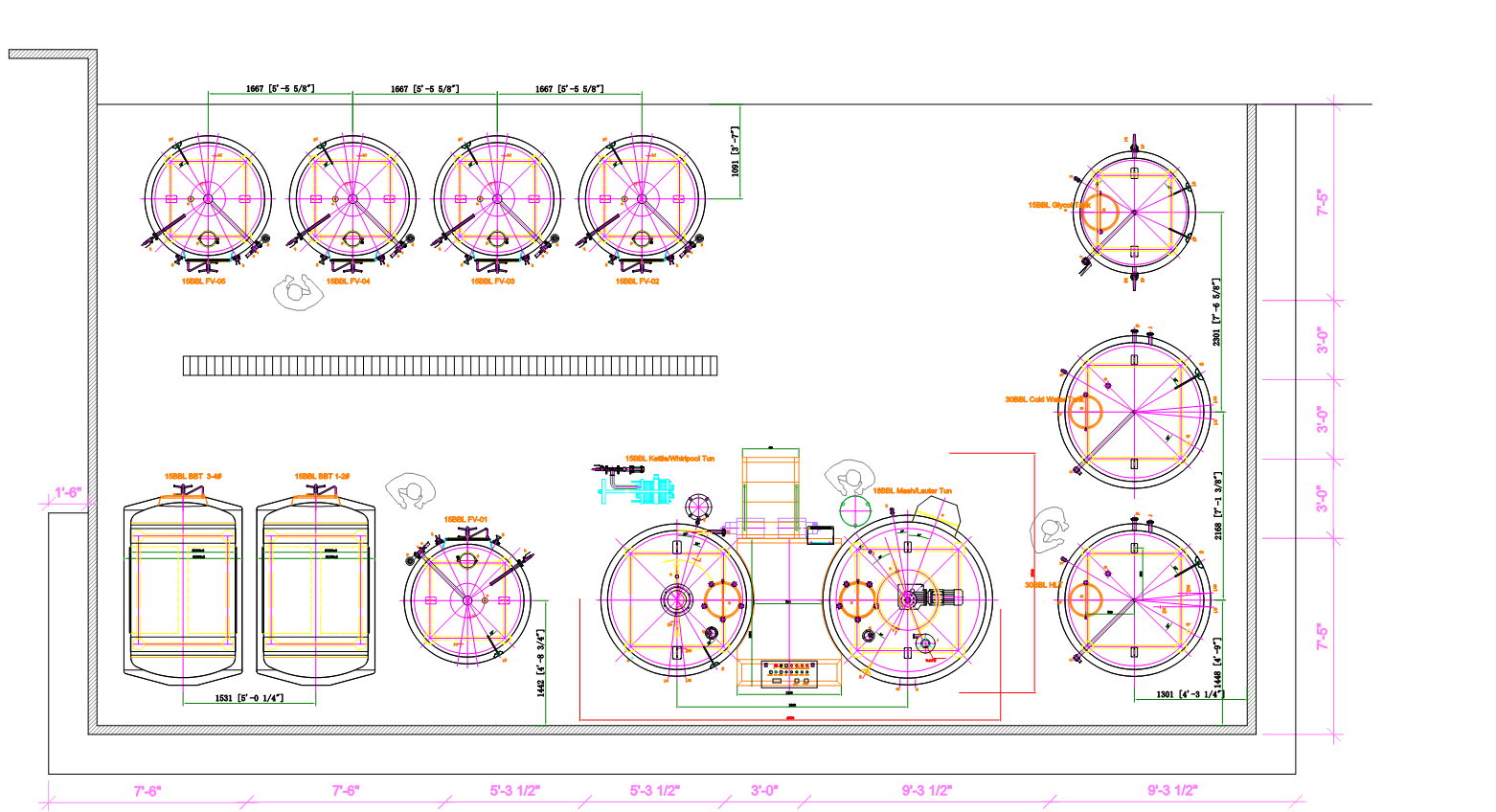

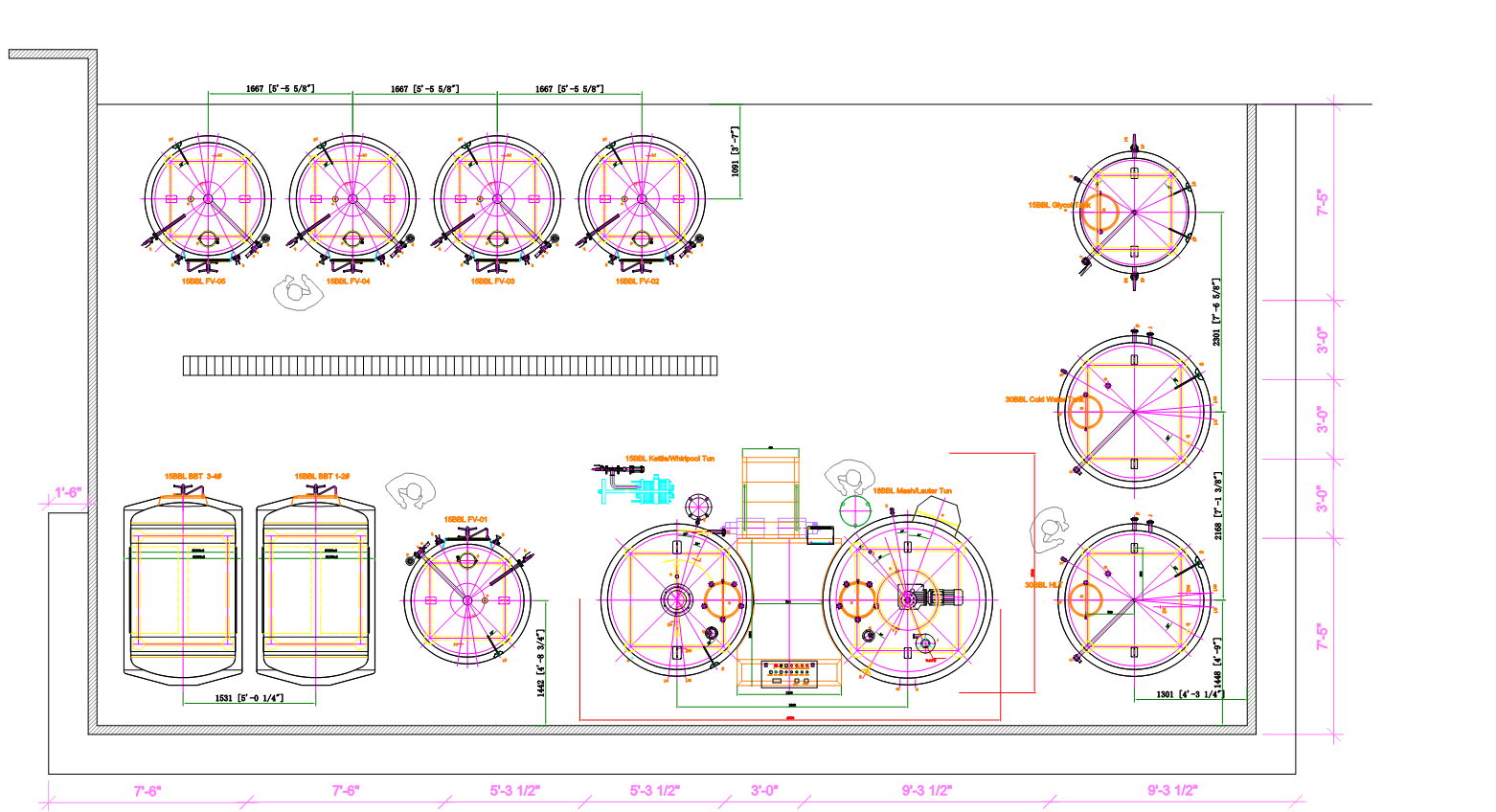

Space utilization: Efficient space utilization is crucial in a brewery layout. Consider the flow of materials and people within the space to optimize the brewing process. Ensure that there is enough space for brewing equipment, fermentation vessels, storage areas, and packaging operations.

Zoning and Separation: Divide the brewery into distinct zones based on the specific activities and processes involved. Common zones include raw material storage, brewhouse, fermentation area, packaging area, cold storage, and offices. Separating these areas helps maintain hygiene, prevents cross-contamination, and ensures that different processes can run simultaneously without interference.

Workflow and process optimization: Design the layout to support a logical and efficient workflow, from raw material handling to brewing, fermentation, packaging, and storage. Minimize unnecessary movement and bottlenecks by arranging the different process areas in a sequential and organized manner.

Regulatory compliance: Breweries are subject to various regulations and codes, including health and safety regulations, zoning laws, and local building codes. Ensure that your layout adheres to these regulations, including proper ventilation, drainage, electrical requirements, and fire safety measures.

Brewing Equipment placement: Carefully consider the placement of brewing equipment to optimize the brewing process. Consider factors such as accessibility for maintenance and cleaning, ease of connecting utilities (water, gas, electricity), and compatibility with adjacent equipment.

Expansion and future growth: Plan for future expansion and growth by considering scalability in your layout design. Leave room for additional equipment, tanks, and storage areas as your production volume increases. This can help avoid costly renovations or reconfigurations in the future.

Utility requirements: Consider the utility requirements of your brewery, such as water supply, electrical power, and wastewater management. Ensure that your layout accounts for these utilities, including the location of utility connections and proper drainage systems.

Safety and hygiene: Breweries require a high level of cleanliness and hygiene to ensure product quality and safety. Design the layout with separate areas for different stages of the brewing process, such as raw material storage, brewhouse, fermentation, packaging, and cleaning areas. Implement proper sanitation protocols and easy-to-clean surfaces to maintain cleanliness and prevent contamination.

Employee comfort and safety: Consider the comfort and safety of brewery staff when designing the layout. Provide well-lit work areas, ergonomic equipment placement, and clear pathways to minimize the risk of accidents or injuries. Also, consider amenities such as break rooms, restrooms, and locker areas for the staff.

Visitor experience: If your brewery includes a taproom or offers tours, consider the visitor experience in your layout design. Create a welcoming and aesthetically pleasing space that allows visitors to observe the brewing process while ensuring their safety and separation from production areas.

Sustainability: Incorporate sustainable practices into your layout design. Consider energy-efficient equipment, waste management systems, water conservation measures, and the use of renewable resources where possible.

It’s worth noting that brewery layouts can vary depending on the size of the operation, the type of beer being produced, and other specific requirements. Working with a professional brewery consultant or architect experienced in brewery design can help ensure a well-planned and optimized layout for your specific needs.