The Essential Function For Hop Gun/Hop Cannon

A hop gun, also known as a hop cannon or hop doser, is a specialized piece of equipment used in the brewing process to add hop flavor and aroma to beer. Its essential function is to inject hops directly into the beer stream after fermentation or during packaging. Here’s how it works and why it’s used:

Function:

1.Dry hopping: The primary function of a hop gun is to dry hop the beer. Dry hopping involves adding hops to the fermented beer after primary fermentation is complete. By injecting hops directly into the beer stream, the hop gun allows for better extraction of hop compounds, such as essential oils and aromatic compounds, without the need for extended contact time.

2.Aroma and flavor enhancement: Dry hopping with a hop gun enhances the beer’s aroma and flavor, imparting a fresh and vibrant hop character. This process is particularly popular in hop-forward beer styles like IPAs (India Pale Ales) and other hoppy ales.

3.Controlled hop dosing: A hop gun allows brewers to control the amount of hops added to the beer, ensuring consistency in the final product. The ability to adjust the hop dosing gives brewers flexibility to achieve desired flavor profiles.

4.Reduced vegetal matter: Using a hop gun helps minimize the amount of vegetal matter, such as hop debris and particulates, entering the final beer. This can improve the beer’s clarity and stability.

5.Time and cost efficiency: Compared to traditional dry hopping methods, using a hop gun can save time and labor. It eliminates the need for manual handling of hop bags or transferring beer between vessels for dry hopping.

Process:

1.Open the top cover (unscrew the bolts).

2.Pour partical type hops into the tank (Adding according to technological conditions, maximum adding volume is 50% of total volume), close the cover and screw the bolt tightly.

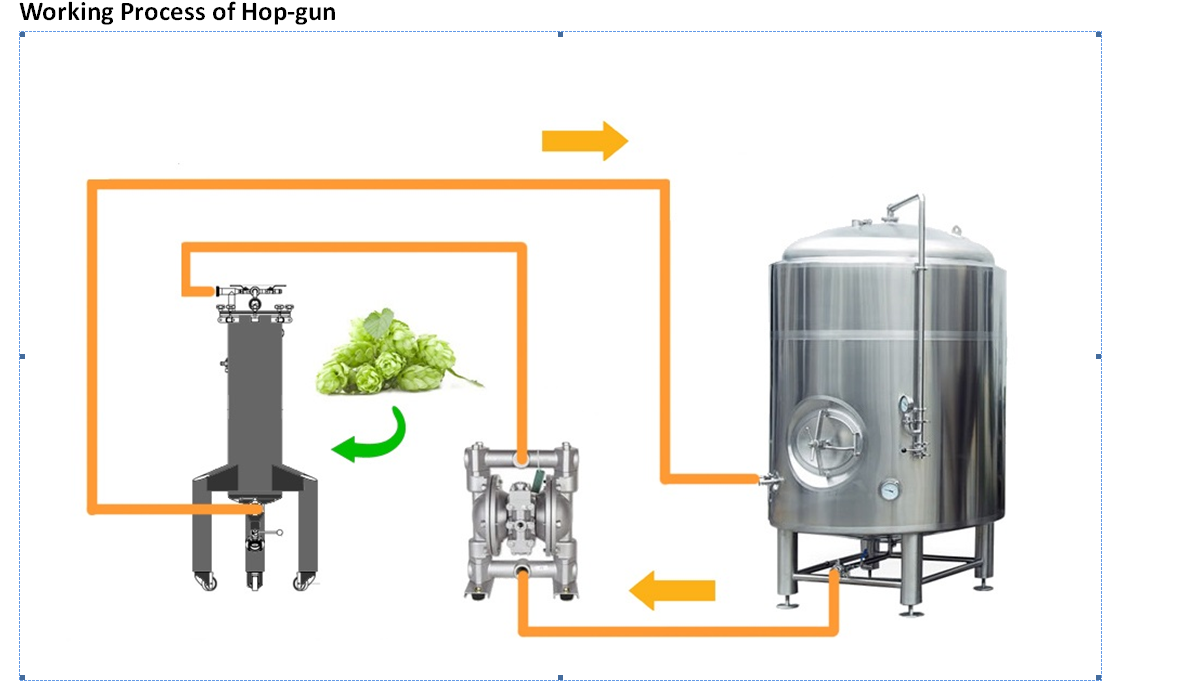

3.According to the above picture, connect the hop-gun and diaphragm pump into the system.

4.Empty the air in the hop-gun vessel — open the top relief valve, make beer flow into the vessel. Along with the entering of beer, air is pushed out slowly. When the hop-gun vessel is full with beer, close the top relief valve.

5.If the pressure inside of vessel is too low, adding CO2 to increase the vessel inside pressure.

6.Then open the valve on the beer recirculation pipeline. Open diaphragm pump for 2-6 hours (time based on the actual brewing technics), make beer flow circularly between hop-gun vessel and fermenter.

7.When recirculation is finished, empty the beer in the hop-gun vessel. CO2 can be added to help for emptying beer. If the fermenter pressure is too low, this procedure can also increase the fermenter pressure and CO2 content.

8.At last, close all valves. Connect with CIP system, clean and sterilize hop-gun vessel and related pipeline.At this point, the dry hopping work of beer in fermenter is finished.

Hop guns come in various sizes and configurations, ranging from manual hand-operated models for smaller breweries to fully automated systems for large commercial operations. The equipment’s design and operation may vary, but the fundamental purpose remains the same: to efficiently and effectively introduce hops into the beer, enhancing its hoppy character and creating delightful aromatic experiences for beer enthusiasts.