The Steps To Designing Your Brewhouse

1.Define Your Brewery’s Goals and Needs:

Determine the production capacity you want to achieve (e.g., barrels or liters per year).

Consider the types of beer you want to produce (e.g., ales, lagers, specialty beers).

Identify any specific equipment or features required for your unique brewing process.

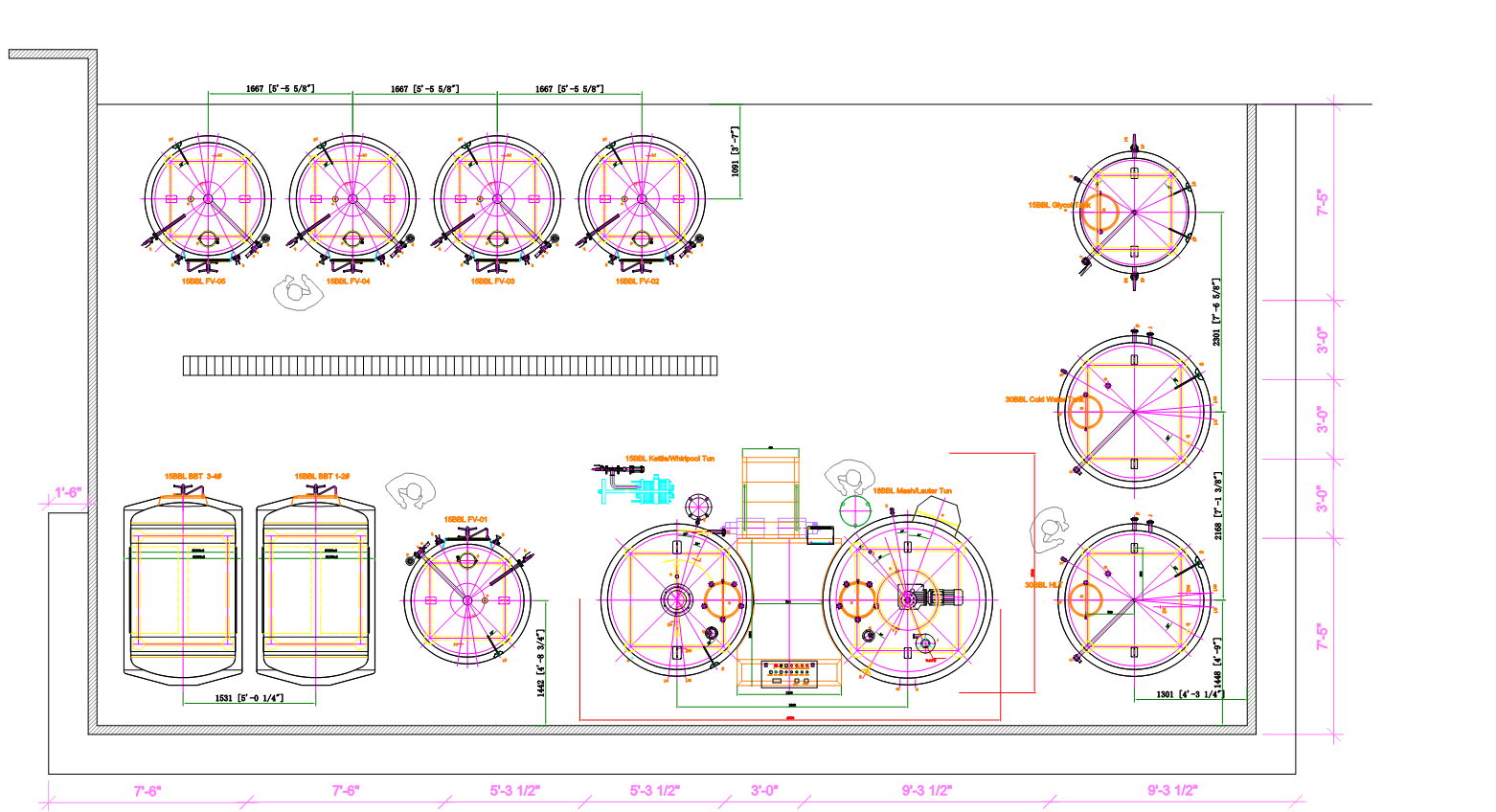

2.Create a Layout and Floor Plan:

Measure the available space for your brewhouse and create a detailed floor plan.

Consider the workflow and efficiency of the brewing process when designing the layout.

Allocate space for various brewing stages, including the brewhouse, fermentation area, packaging area, and storage.

3.Select Brewhouse Equipment:

Choose the appropriate brewhouse equipment, including mash tuns, fermenters, boil kettles, and hot liquor tanks.

Consider the material of the equipment (e.g., stainless steel) for durability and sanitation.

Ensure that the equipment aligns with your production capacity and brewing goals.

4.Plan Utility Requirements:

Determine the utility requirements, such as electrical power, water supply, steam, and drainage.

Ensure that your building’s infrastructure can support the utility needs of the brewhouse.

5.Consider Safety and Compliance:

Comply with local building codes, zoning regulations, and health department requirements for breweries.

Incorporate safety features, such as emergency shut-off valves, fire suppression systems, and adequate ventilation.

6.Design the Brewing Process:

Develop a detailed plan for your brewing process, including the mash schedule, lautering, boiling, and fermentation.

Determine the necessary temperature control and automation systems for consistency and quality.

7.Account for Future Growth:

Anticipate future growth and expansion when designing your brewhouse.

Allow for the possibility of adding more fermentation tanks or expanding production capacity.

8.Consider Environmental Sustainability:

Incorporate eco-friendly practices and equipment to minimize water and energy consumption.

Explore options for waste management and recycling to reduce environmental impact.

9.Budget and Financing:

Estimate the costs associated with the brewhouse design, equipment, and construction.

Develop a comprehensive budget and explore financing options if needed.

10.Work with Experts and Consultants:

Consider seeking advice from experienced brewers or brewery consultants who can provide insights and recommendations.

Collaborate with architects and engineers who have experience in designing commercial brewing facilities.

Review and Refine the Design:

Review the design with your team and make necessary adjustments based on feedback and practical considerations.

Obtain Permits and Approvals:

Submit the brewhouse design and plans for relevant permits and approvals from local authorities.

Build and Install the Brewhouse:

Engage qualified contractors to construct the brewhouse and install the equipment.

Ensure that the installation follows best practices and industry standards.

Test and Commission the Brewhouse:

Conduct thorough testing and commissioning of the equipment to ensure it operates as intended.

Start Brewing:

Once the brewhouse is operational, begin brewing and enjoy the fruits of your labor!

Remember that designing a brewhouse is a complex process that requires attention to detail and a clear vision for your brewery’s future. Take the time to plan and collaborate with experts to ensure that your brewhouse meets your brewing goals and provides a solid foundation for your brewery’s success.