2000L Automatic Brewing System

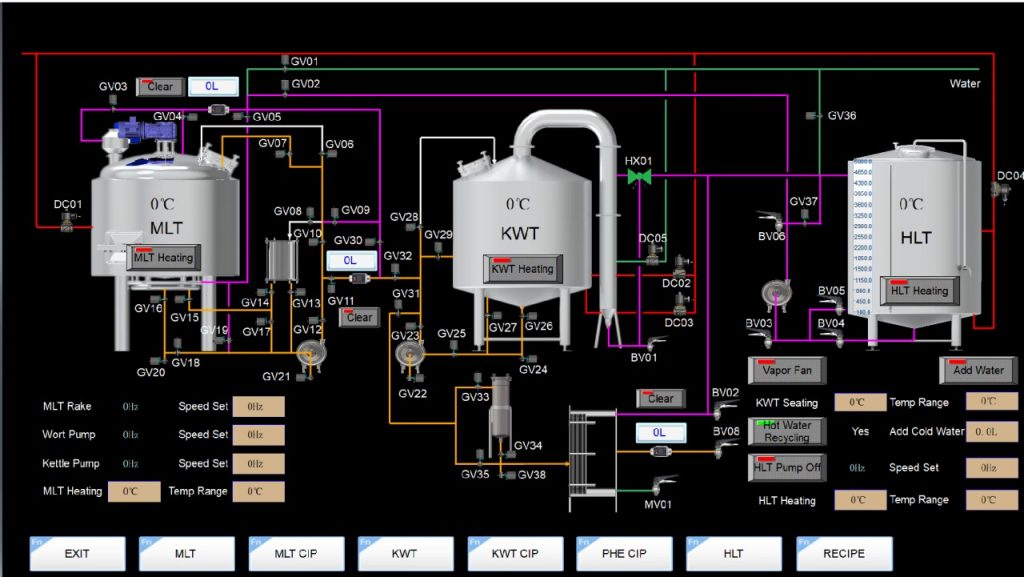

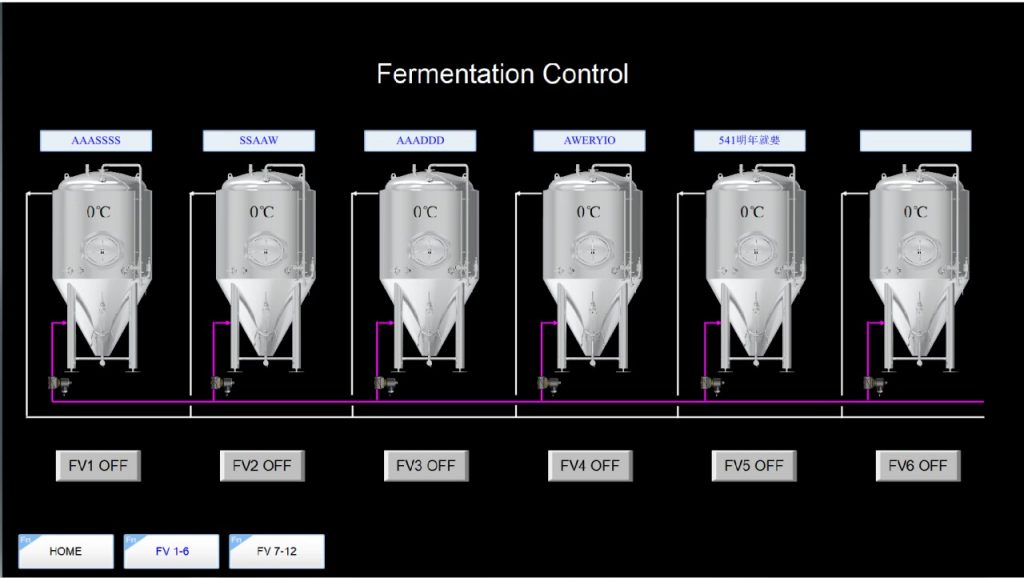

NFE provides automatic brewing systems according to customers requirements. With pneumatic butterfly valves, pressure sensors, IFM flowmeters, liquid level sensors, this automatic brewing system can realize the automation of each step of the brewing process. It can save a lot of labors and enhance productivity.

Advantages

|

|

This 2000L automatic system is equipped with pneumatic butterfly valves, enabling full automation of the mashing process, including milling, mashing, lautering, recirculation, sparging, boiling, and whirlpooling. With just a click of the corresponding command button, brewers can automatically control the opening and closing of valves and pumps, significantly improving efficiency and reducing manual labor.

Parameter

|

|

|

NFE’s fully automated mashing system offers a streamlined, high-precision brewing experience, making it an ideal choice for small and medium-sized breweries and craft beer brands with high standards for quality. By combining advanced automation with intelligent operation, this system brings significant advantages to craft brewing:

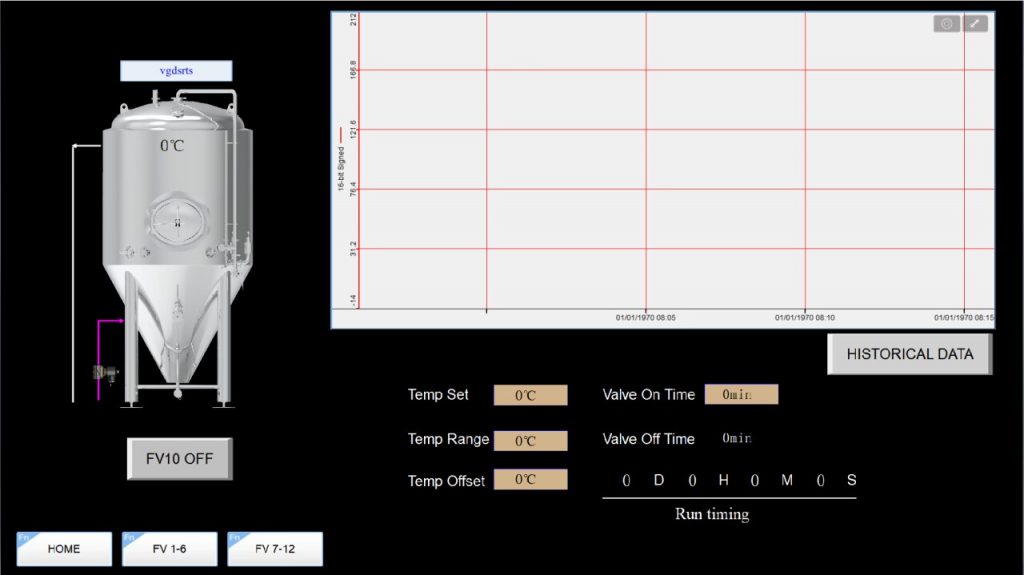

1. Precise Control for Consistent Brewing Quality

Equipped with precise controls for temperature, timing, and agitation, NFE’s automated mashing system maintains optimal conditions throughout the mashing process. This ensures batch-to-batch consistency, helping brewers deliver a high-quality product every time.

2. Intelligent Operation for Simplified Brewing

The system’s automation simplifies the brewing process, allowing brewers to set key parameters effortlessly through an intuitive control panel. This reduces manual labor, making the system highly user-friendly and boosting management efficiency.

3. Labor Savings and Increased Efficiency

Once parameters are set, the fully automated system completes each stage of the mashing process autonomously—from heating and agitation to cleaning—minimizing the need for manual intervention. This not only reduces labor costs but also shortens production times, significantly increasing brewing efficiency.

4. Energy-Efficient Design for Reduced Operating Costs

Designed with energy efficiency in mind, the system precisely controls heating duration and intensity to reduce unnecessary energy consumption. Scientific design of the heating and cooling systems allows for rapid temperature changes while keeping energy use low, helping brewers lower their operating costs.

5. Easy Cleaning and Maintenance

With an integrated CIP (clean-in-place) system, the system automatically executes cleaning procedures after each mashing cycle, ensuring hygiene standards and reducing cleaning time. Built for durability and easy maintenance, the system minimizes downtime and long-term maintenance costs.

NFE’s fully automated mashing system not only improves production efficiency but also delivers consistent quality and flavor for every batch. With its high efficiency, energy savings, and intelligent design, it stands out as the ideal choice for breweries seeking an advanced, reliable brewing solution.

Contact

Contact

E-mail

E-mail

Message

Message