Control System for Brewing Equipment

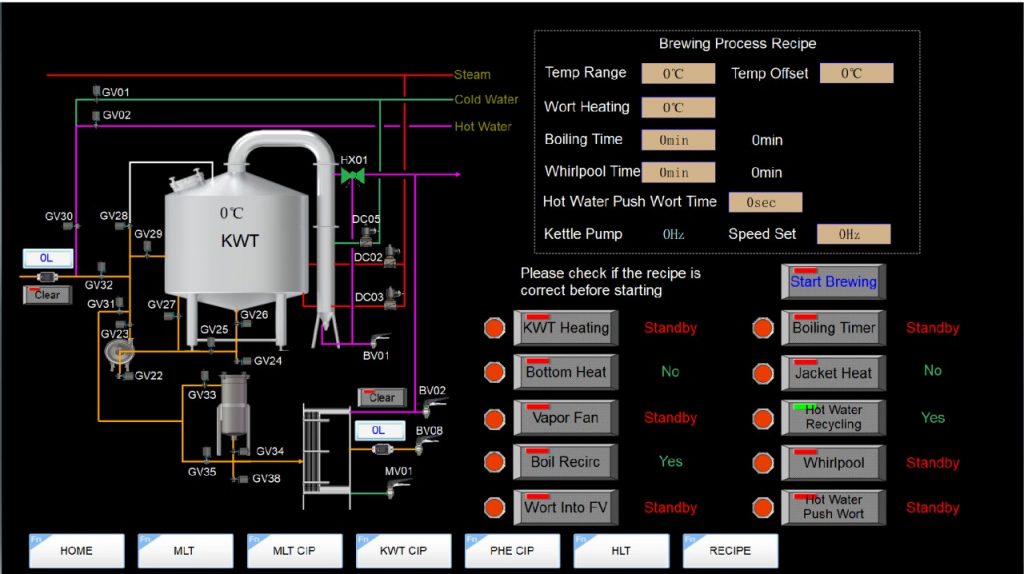

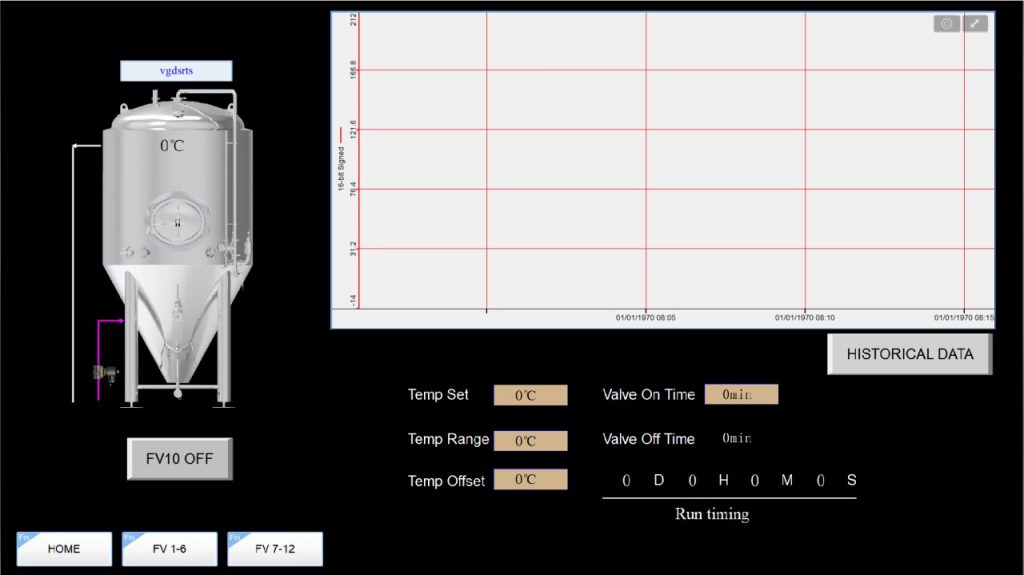

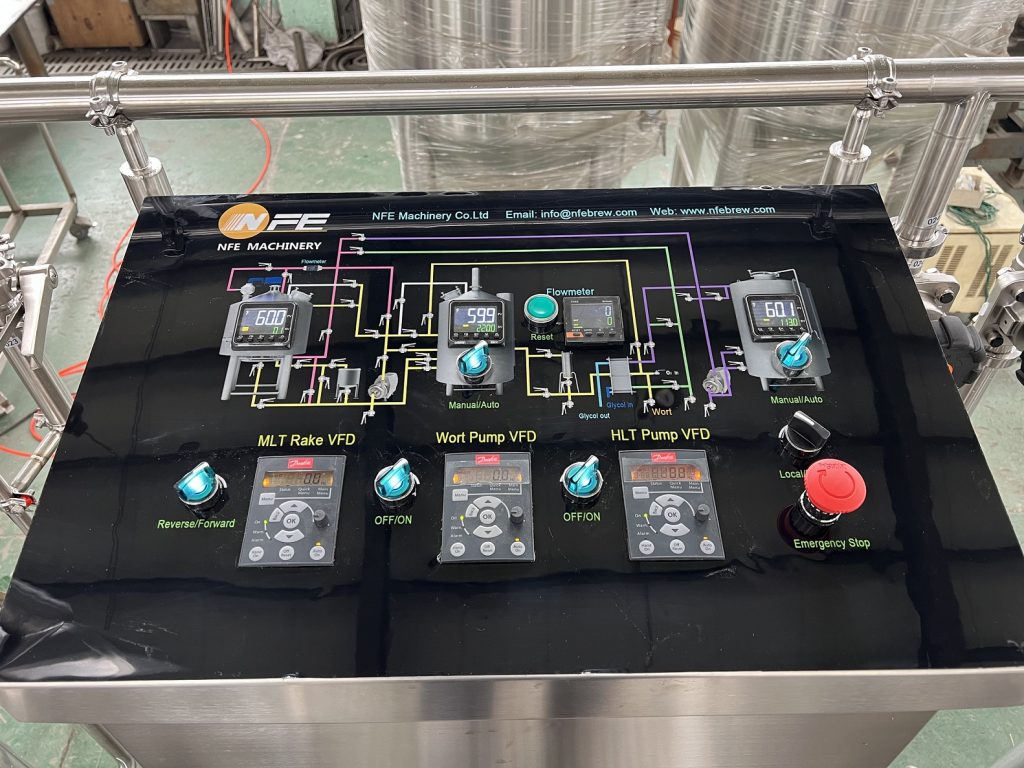

Control panel system is an important component of a brewery system, as it allows the brewer to monitor and control various aspects of the brewing process. A control panel system typically includes a central control unit, which is connected to various sensors, valves, and other components throughout the brewery. NFE can provide both semi-automatic button-controlled cabinets and fully automatic touchscreen PLC control systems.

Advantages

|

|

1.Advantages of NFE’s Automated PLC Control System for Beer Brewing

NFE’s automated PLC control system enables precise, hands-free management of the entire beer brewing process. By eliminating the need for manual valve and pump operation, it significantly enhances efficiency, consistency, and convenience for brewers.

Key Benefits:

-

Complete Process Automation

-

Automates mashing, lautering, boiling, fermentation, and carbonation with pre-programmed sequences.

-

Ensures repeatable, error-free operations for consistent beer quality.

-

-

Time & Labor Savings

-

Brewers no longer need to manually open/close valves or start/stop pumps—reducing physical workload and human error.

-

Frees up brewmasters to focus on recipe development, quality control, and innovation rather than repetitive tasks.

-

-

Precision Control & Consistency

-

Real-time monitoring & adjustments of temperature, pressure, flow rate, and timing.

-

Maintains strict adherence to brewing parameters, ensuring batch-to-batch uniformity.

-

-

Enhanced Safety & Reliability

-

Automated safety interlocks prevent overheating, overflow, or equipment damage.

-

Alarm notifications for deviations (e.g., temperature spikes, pump failures) enable quick troubleshooting.

-

-

Remote Monitoring & Data Logging

-

Touchscreen HMI + SCADA integration allows brewers to track progress and adjust settings remotely.

-

Data recording for compliance, quality analysis, and process optimization.

-

-

Scalability & Customization

-

Adaptable to small craft breweries or large-scale production with modular expansions.

-

Supports integration with CIP (Cleaning-in-Place) systems, IoT, and smart brewery solutions.

-

Ideal for Modern Breweries:

✔ Craft brewers seeking efficiency without sacrificing quality.

✔ Industrial breweries requiring high-volume, repeatable production.

✔ Startups aiming for automation from day one.

|

|

2. Semi-Automatic Button-Controlled Cabinets:

-

-

Operation: Operators manually initiate processes via push buttons, switches, or selector knobs.

-

Applications: Ideal for simpler processes requiring human oversight, such as batch operations or equipment testing.

-

Features:

-

Basic start/stop, emergency stop, and mode selection.

-

Reliable and cost-effective for low-complexity tasks.

-

-

Parameter

|

|

|

NFE offers a comprehensive range of high-performance control systems tailored to the needs of breweries—from small craft operations to large industrial facilities. Our systems are designed for stability, precision, and long-term reliability, ensuring smooth and efficient beer production.

Key Features of NFE Brewery Control Systems:

-

Robust & Dependable Performance

-

Built with industrial-grade components to withstand harsh brewing environments (moisture, temperature fluctuations, vibrations).

-

Redundant fail-safes minimize downtime and prevent production losses.

-

-

Flexible Solutions for Every Brewery

-

Semi-automatic control panels – Cost-effective for smaller breweries with manual oversight.

-

Fully automated PLC + HMI systems – Advanced automation for mashing, fermentation, and packaging.

-

Scalable architecture – Easily expandable as production grows.

-

-

User-Friendly Operation

-

Intuitive touchscreen interfaces allow brewers to monitor and adjust processes effortlessly.

-

Pre-programmed recipes ensure consistency across batches while allowing customization.

-

-

Seamless Integration

-

Compatible with CIP (Clean-in-Place) systems, quality sensors, and IoT-enabled smart brewing solutions.

-

Supports remote monitoring & data logging for real-time analytics and compliance reporting.

-

Why Brewers Trust NFE:

✔ Proven track record in brewery automation worldwide.

✔ 24/7 technical support and maintenance services.

✔ Customizable solutions to fit unique production needs.

Whether you’re a startup microbrewery or an established beer brand, NFE delivers stable, efficient, and future-proof control systems to elevate your brewing process.

Interested in a system tailored to your brewery? Contact us for a consultation!