800 cans/hour Beer Canning Line

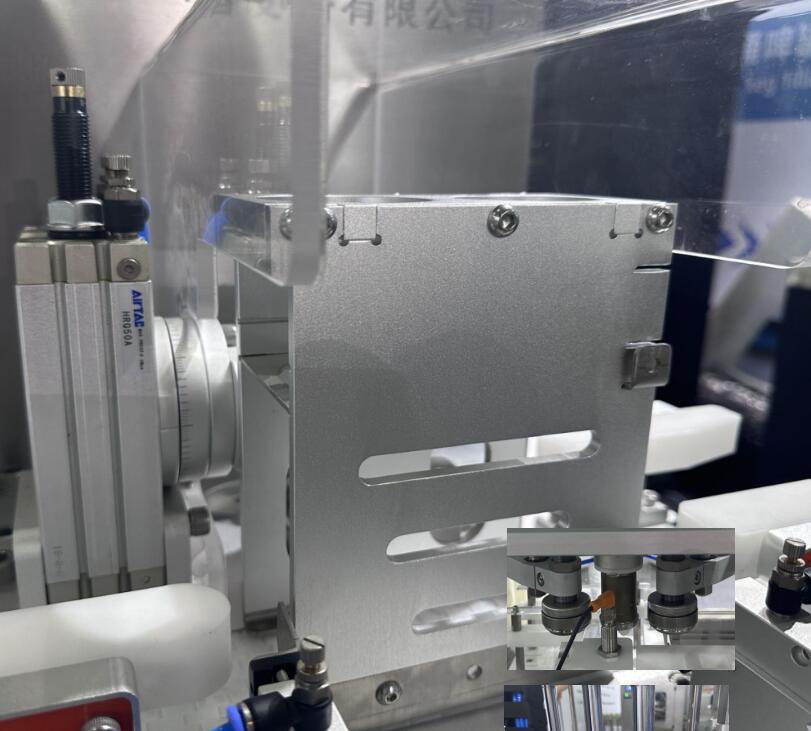

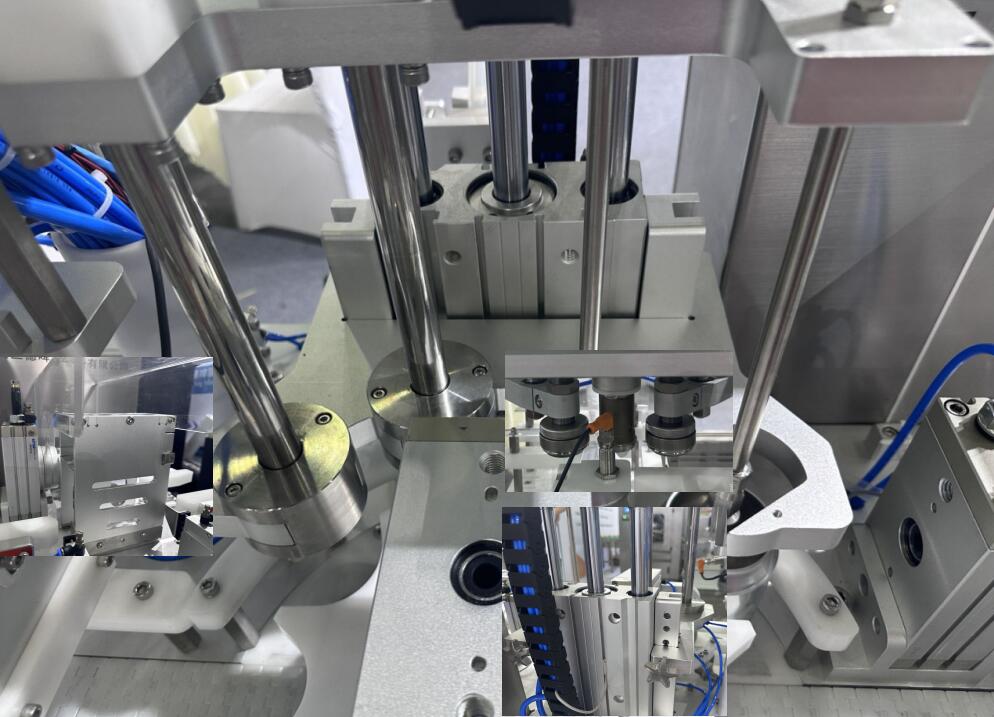

NFE smart can rinser/filler/seamer is specially designed for microbrewery to rinse can,fill beer into cans and seal cans automatically. Considering the limited area of most microbreweries, this machine is designed as a small size and fast filling speed, sanitary, movable, simple operation. The whole work is control by PLC programming. It can be used inline to be connected with other equipment, such as can depalletizer, labeler, date printer, etc. No Doubt that it is the ideal can filler for all the microbreweries.

Advantages

|

|

|

|

Craft working process

Craft process: put can(on the sorting table)→press green button (AUTO mode)→Enter the rinsing staion→Enter the CO2 pre-purging station(CO2 in, and air out)→Enter the filling station (the number of cans is a multiple of 4)→ filling cylinder down (beer valve is opened and filling begins, isobaric filling)→ filling is completed (the electrode detection of the four stations should be connected, and the position of the electrode can be adjusted according to different can types)→can enters the falling lid station→fall lid is completed to enter the seaming station→seaming is completed to enter the spray station→completed

Parameter

Specification Sheet of Can Rinser/Filler/Seamer 2-2-1

| 1 | Size:W*L*H | 1.20x 0.80×1.80M | |||

| 2 | Weight | 200KG | |||

| 3 | Packing Size (L*W*H) | 1.35×0.95×2.00M | |||

| 4 | Gross Weight | 350KG | |||

| 5 | Capacity | 300~600PCS|2 STATION | |||

| 6 | Power | Singel Phase 110V-240VAC 50/60Hz is default | |||

| 7 | Power consumption | 900W | |||

| 8 | Main Material | AISI304, Aluminum Alloy and POM | |||

| 9 | Beer Source Requirement | Temperature: 30.2 – 32F (-1 to 0C) Carbonation: 2.4 to 2.7 volumes CO2 (4.6 to 5.2 g/L CO2) Pressure:22psi(0.15MPa) Connection: 1.5″ Tri-clamp |

|||

| 10 | CO2 Regulator | 58-65 psi(0.4MPa-0.45Mpa) from plant system connected to canning system with 10mm OD barbed fitting | |||

| 11 | Air Regulator | 87-102 psi(0.6MPa-0.7Mpa) from plant system connected to canning system with 10mm OD barbed fitting | |||

| 12 | Time setting way | F110 Siemens PLC 200 smart and IEV3 Touch Screen | |||

| 13 | Seamer | Cemented Carbide Panasonic Motor |

|||

| 14 | Dissolved Oxygen | ≤20ppb | |||

| 15 | Can type | The machine can be configured for nearly all standard can sizes! Change over between different can dimensions is a snap, requiring only a few simple tools and less than 30 minutes. | |||

| 16 | Rinse function | 3S/pc(adjustable) | |||

| 17 | Spray function | 2S/pc(adjustable) | |||

| 18 | Package | Composite board boxes | |||

| 19 | Lead time | 35days | |||

Contact

Contact

E-mail

E-mail

Message

Message